KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

PRODUCT LIBRARY

designboom's earth day 2024 roundup highlights the architecture that continues to push the boundaries of sustainable design.

the apartments shift positions from floor to floor, varying between 90 sqm and 110 sqm.

the house is clad in a rusted metal skin, while the interiors evoke a unified color palette of sand and terracotta.

designing this colorful bogotá school, heatherwick studio takes influence from colombia's indigenous basket weaving.

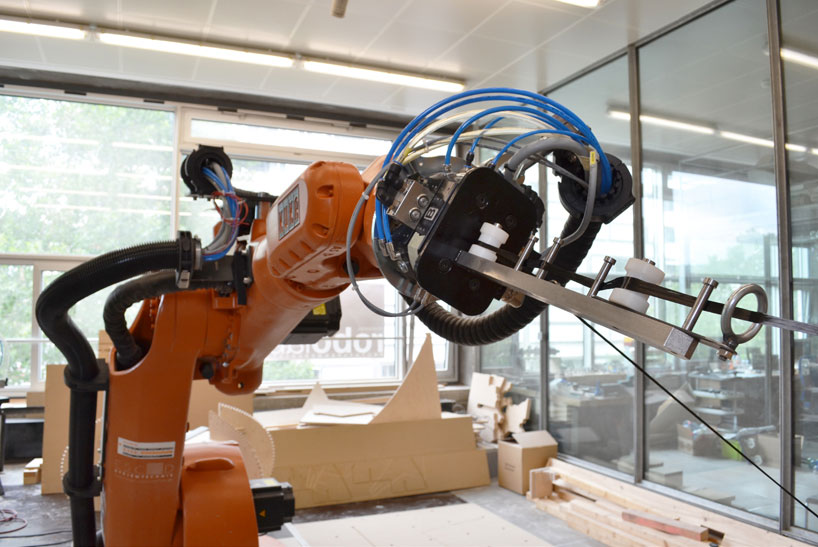

preliminary testing – filament winding system showing the effector

preliminary testing – filament winding system showing the effector preliminary testing – small scale winding

preliminary testing – small scale winding dry winding tests – the setup shows the 6-axis robot coupled with an external seventh axis which turns the entire frame

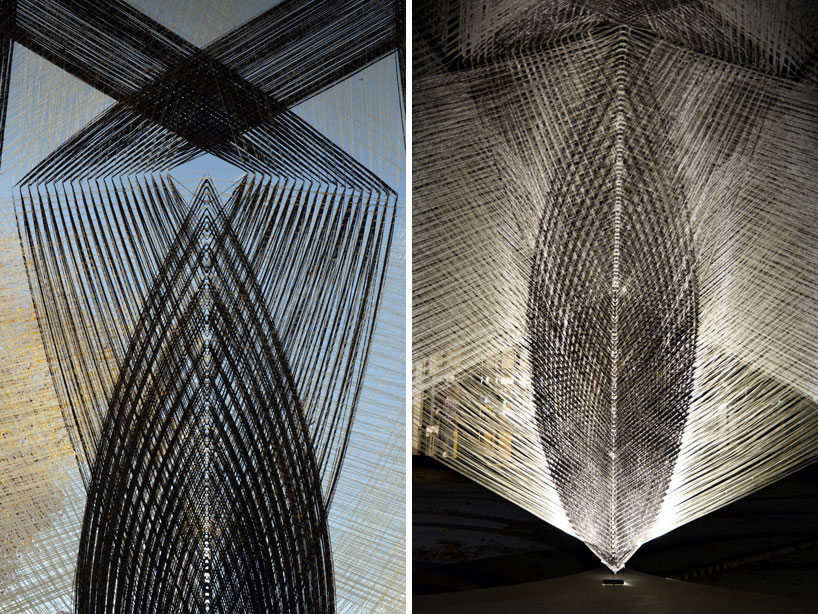

dry winding tests – the setup shows the 6-axis robot coupled with an external seventh axis which turns the entire frame previous sequences of the winding process serve as an integral mould for subsequent layers for specific structural purposes

previous sequences of the winding process serve as an integral mould for subsequent layers for specific structural purposes transportation from the construction site to the final location

transportation from the construction site to the final location top view of the finished pavilion

top view of the finished pavilion east elevation

east elevation interior view

interior view close up of the woven glass and carbon fibres

close up of the woven glass and carbon fibres (left): close up of roof connection(right): night view from inside

(left): close up of roof connection(right): night view from inside (top): the whole digital process was linked in an information chain, also including the input parameter(bottom): within this chain the winding logic was developed and optimized, consisting of five patterns

(top): the whole digital process was linked in an information chain, also including the input parameter(bottom): within this chain the winding logic was developed and optimized, consisting of five patterns