KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

happening now! at milan design week 2024, samsung creates a world where the boundaries between the physical and digital realms blur.

PRODUCT LIBRARY

watch our livestream talk with BMW Design at 19:15 CEST on monday 15 april, featuring alice rawsthorn and holger hampf in conversation.

connections: +300

discover our guide to milan design week 2024, the week in the calendar where the design world converges on the italian city.

connections: 28

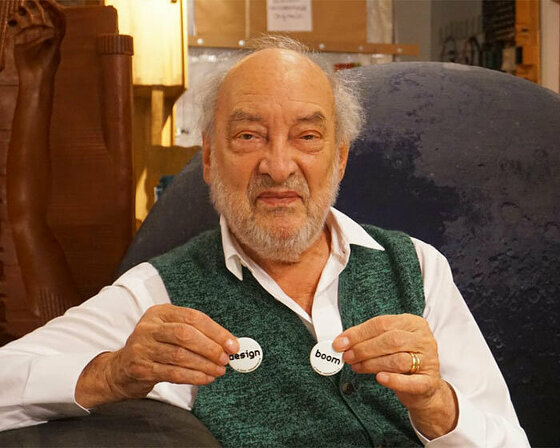

'despite dealing with health-related setbacks, gaetano remained positive, playful and ever curious,' pesce's team said in a post confirming his death.

connections: +130

tia thuy nguyen reimagines lady dior as a sculptural artwork that captures light and shadow through transparent quartz crystals.

connections: +250