KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

PRODUCT LIBRARY

we're getting ready for the pre-opening launching today until friday, with public access scheduled for the 20th.

connections: 6

watch our livestream talk with BMW Design at 19:15 CEST on monday 15 april, featuring alice rawsthorn and holger hampf in conversation.

connections: +300

the solo show features five collections, each inspired by a natural and often overlooked occurence, like pond dipping and cloud formations.

discover our guide to milan design week 2024, the week in the calendar where the design world converges on the italian city.

connections: 31

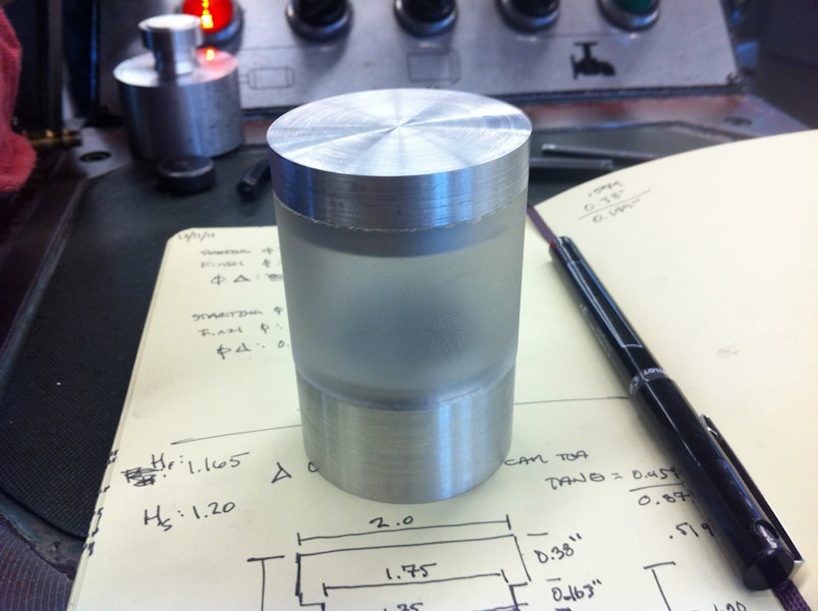

One of the first completed light vials after being turned down on the lathe.

One of the first completed light vials after being turned down on the lathe. The LED and electronics in the base of the light prior to testing.

The LED and electronics in the base of the light prior to testing.