series production of the bugatti ‘chiron’ supercar is rapidly gathering pace. twelve super sports cars are currently under construction in the french luxury brand’s production facility, the ‘atelier’ at the company’s headquarters in molsheim, north-east france. on average, about six months pass between the start of production and the final delivery of a ‘chiron’. twenty specialists in the atelier assemble the powerful, luxurious production supercar from over 1800 individual parts, working solely by hand. as expected, the supercar is subjected to the most stringent acceptance tests and quality controls before it is delivered. many modifications to the facility were made for the assembly of the 1500 horsepower super-sportscar to take account of its higher performance and the more complex nature of the new product and its production process.

the bugatti atelier in molsheim, north-east france

all images © bugatti /benjamin a. monn

only when a bugatti customer has signed off the vehicle’s does production planning start. normally, a ‘chiron’ takes about nine months for this journey from configuration through to delivery. the more unusual a customer’s wishes in terms of materials, colors or other details are, the more time will be required. when a production slot has been assigned to a vehicle, the parts that are needed are then ordered. from here, the countdown begins and it will take about six months up to the delivery of the car. now, bugatti’s suppliers, who are located throughout europe, work hard to deliver the parts that are needed to molsheim in time for assembly.

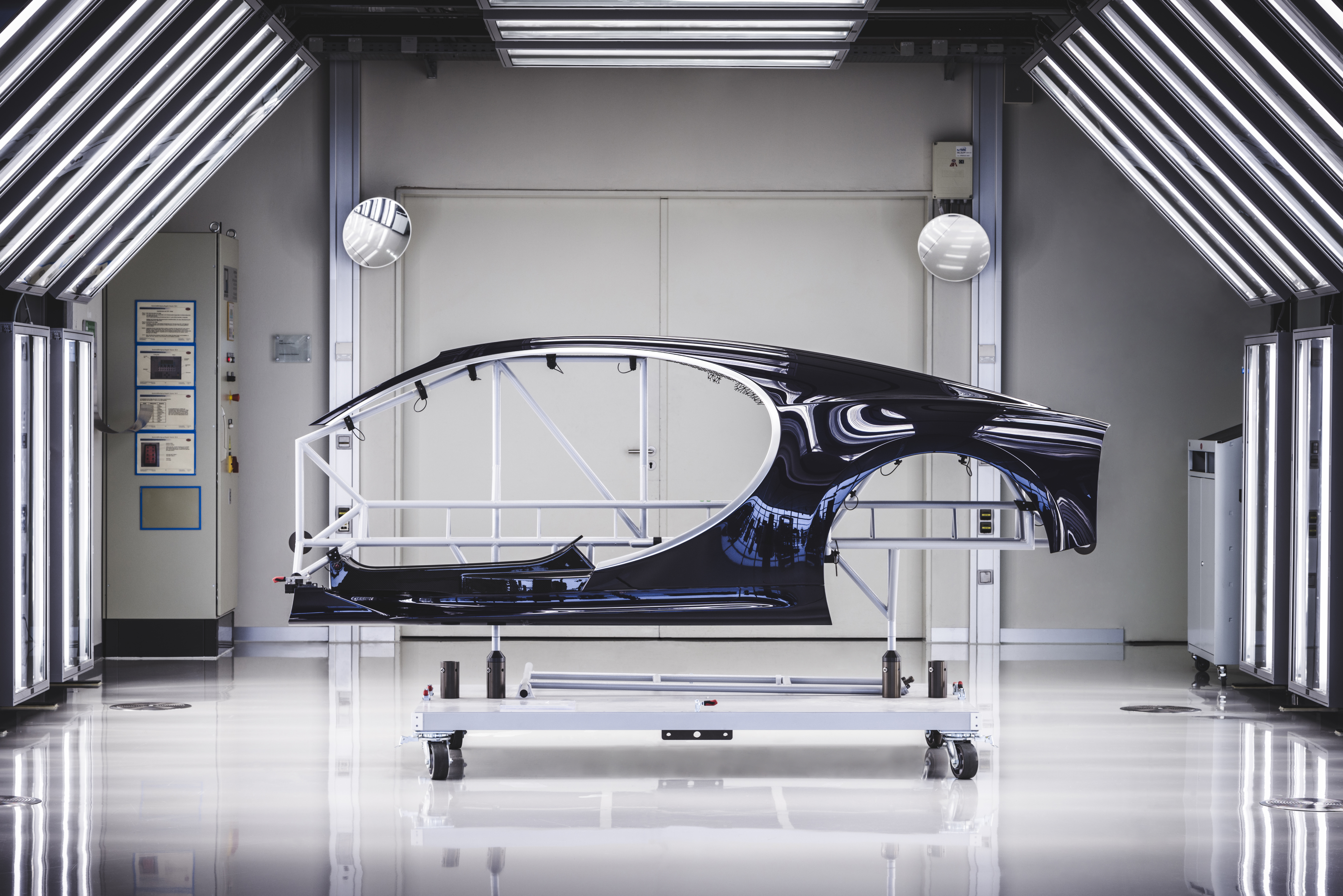

one month before the start of production, the bodyshell is assembled with the monocoque and chassis substructure to ensure that everything fits together seamlessly. it takes about three weeks to apply the various coats of paint. in the case of visible carbon fiber, six layers are required. for the top coat, up to eight layers may be needed depending on whether the finish that has been ordered is uni, metallic or pearlescent. the process is so time-consuming as all layers are applied by hand, plus each individual coat needs to be sanded down, and polished before work can start on the next coat.

the production building for the ‘chiron’, which bugatti calls ‘atelier’, has a floor space of more than 1000 square metres. it was inaugurated in 2005 and has an oval configuration, based on the french brand’s logo, the bugatti ‘macaron’. it was designed by the architect professor gunter henn from munich. for over ten years, the ‘veyron 16.4’ and its derivatives were built here. for the ‘chiron’, many modifications were made to the atelier and its facilities to take account of new product properties and increased complexity of the production process.

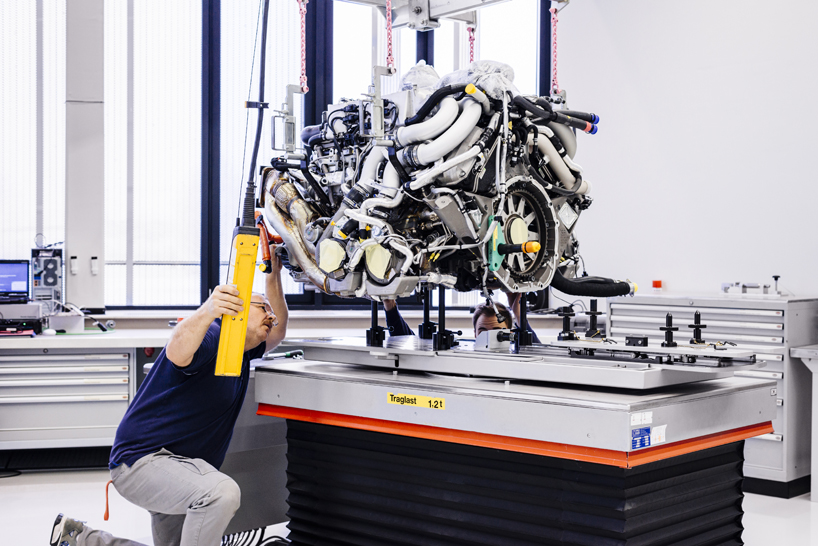

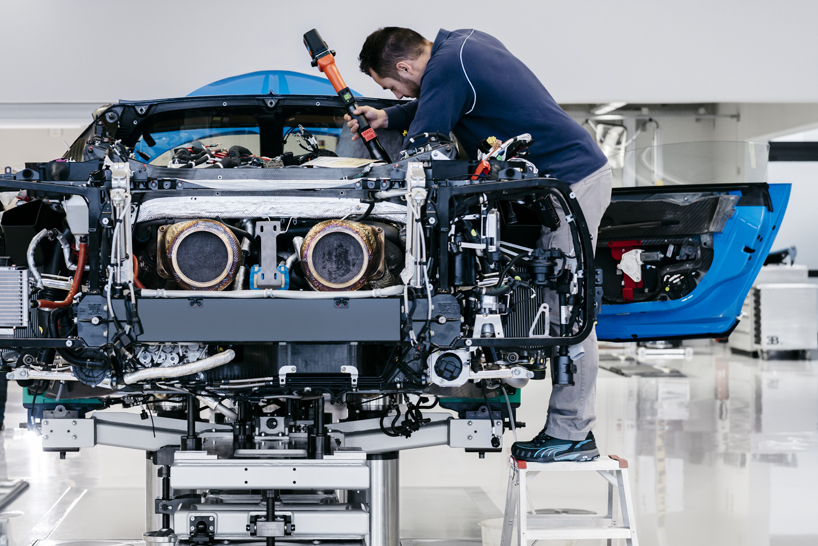

no conveyor belts nor robots can be found at the molsheim facility. people work at stations, as in the workshop of a formula one team. all in all, there are twelve stations. at the first station, the powertrain is prepared for assembly. this is supplied pre-assembled from the volkswagen group engine plant in salzgitter, where specialists build the 1500 ps engine in a pilot hall equipped exclusively for bugatti, and then put it through its paces on a test bench for eight hours. at the same time, a similar procedure is applied to the 7-speed dual-clutch transmission which has been made bigger and stronger to accommodate the high power output of the supercar, and the gigantic torque of 1600 Nm.

there are two chassis building platforms in the atelier, where three employees spend about one week on the assembly. the rear end of the vehicle is built round the powertrain. at the same time, the monocoque and the front end are joined together and equipped with the wiring harnesses required. the pipes connecting the engine at the rear with the radiators at the front are also installed, as cooling is crucially important in the ‘chiron’. the vehicle is equipped with three water pumps, one large pump for the high-temperature cycle and two smaller pumps for the lowtemperature cycle.

the only electronic tool used in chassis assembly is an EC nutrunner system. this allows a data curve of each bolt tightened on the chassis to be stored on a computer connected to the system, which then gives the assembly worker a signal when the right torque value is reached. there are more than 1800 bolted joints on a the supercar, with documentation required for 1068. the high point of chassis assembly is definitely the marriage – joining the monocoque and the rear end. fourteen titanium bolts ensure that the bond between the two units is durable and extremely strong. titanium was selected to save weight; each bolt only weighs 34 grams.

after this stage, the chassis travels a few metres to the rolling dynamometer, the most powerful of its type in the world. this is the part of the production facility that called for the greatest investment in preparation for the ‘chiron’. the modifications, including larger electric cables, were necessary as the old rolling dynamometer could not absorb the 1500 horsepower and 1600 Nm. the new unit is so powerful that it can produce electricity with a current of up to 1200 amps during operation. bugatti then feeds the excess power generated back to the local grid in molsheim.

once the supercar has passed all of the stringent tests on the rolling dynamometer, it is fitted with its exterior skin at the following station. here, the carbon exterior parts are installed on the vehicle. as some of the individual lightweight parts are very large and fragile, this work is extremely demanding, which is why a pre-assembly stage was introduced. pre-assembly is completed in bugatti’s new technology centre, which is located just 200 metres away from the atelier. the lighting conditions in this assembly hall are the same as in the atelier, which means that any problems with the paintwork or damage to individual parts can be identified and remedied before the parts are installed on the vehicle. it takes between three and four days before the body parts have been installed on the ‘chiron’ and the gaps and joints have been precisely adjusted.

the next stage is a water test: here, the bugatti is exposed to monsoon rain of varying intensity for 30 minutes to show that there are no leaks. the interior fittings are only installed when this test has been completed. here, two team members make sure that all the parts are installed in the right place in the interior of the supercar, a process that normally takes up to three days. customers can choose between a luxurious variant with full leather trim, or a more sporty combination of leather + carbon fiber.

when the interior has been completed, the ‘chiron’ is prepared for its test and final inspection drive. the entire supercar is covered by a strong transparent plastic foil, taking a whole day alone. a further day is required for removing the foil and cleaning the vehicle following the test drive. before it leaves the atelier for the first time on the test drive, the electronic functions of the vehicle are tested and the track of the wheels is adjusted. during the test drive it is driven 300 km through the vosges to the airport in colmar, where it completes test of functions requiring speeds in excess of 250 km/h on the runway. the return trip is covered at a more ‘relaxed’ pace on the autobahn to allow the vehicle to cool down. if the test driver gives it the thumbs up following the trip, the transmission oil is changed and the original wheels and underbody are installed in the atelier. the car then completes a final test drive over 50 km before final ‘dynamic approval‘ is given.

at this stage, the ‘chiron’ is transferred to the paint booth, where it is prepared for the final finish. all the protective foils are removed and the vehicle is then cleaned and polished. the cosmetic preparation of the supercar takes two days before it is transferred to the light tunnel. here, a team member carries out a relentless inspection of the finish for more than six hours, after which the bugatti returns to the paint booth. the team member is then devoted to intensive optimization until all the visible blemishes have been removed. after about two months, the ‘chiron’ leaves the production facility. during this time, twenty employees, including two women, have assembled a total of about 1800 individual parts to create one the world’s most powerful and exclusive production supercars.

BUGATTI (32)

CAR DESIGN (793)

PRODUCT LIBRARY

a diverse digital database that acts as a valuable guide in gaining insight and information about a product directly from the manufacturer, and serves as a rich reference point in developing a project or scheme.