KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

PRODUCT LIBRARY

designboom is presenting the sound machines of love hultén at sónar festival in barcelona this june!

connections: 74

BMW releases the upgraded vision neue klasse X, with a series of new technologies and materials especially tailored for the upcoming electric smart car.

following the unveiling at frieze LA 2024, designboom took a closer look at how the color-changing BMW i5 flow NOSTOKANA was created.

connections: +630

each unit draws inspiration from emergence, featuring a hexahedron-based structure that facilitates integration into larger systems.

connections: 96

the body is made from

the body is made from  caption woven cherry skins and tessellated end grain balsa core

caption woven cherry skins and tessellated end grain balsa core the front

the front  the laminated wood veneer chassis

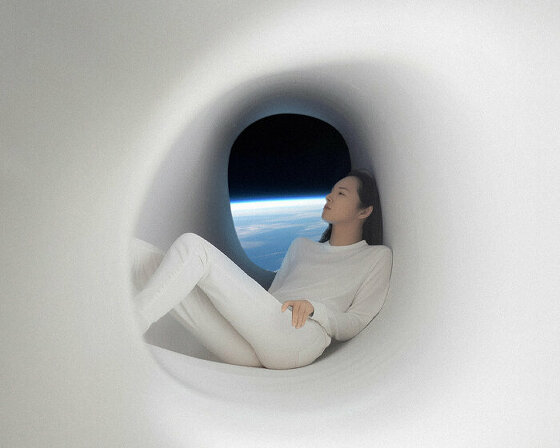

the laminated wood veneer chassis  the interior cabin

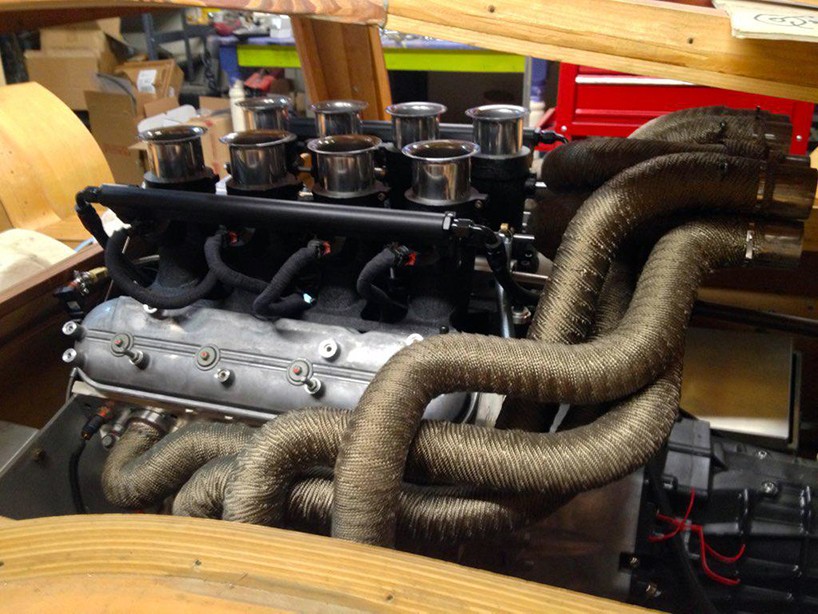

the interior cabin the small block V8 engine

the small block V8 engine three piece forged aluminum rims with laminated wood center section

three piece forged aluminum rims with laminated wood center section concept rendering

concept rendering