KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

PRODUCT LIBRARY

BMW releases the upgraded vision neue klasse X, with a series of new technologies and materials especially tailored for the upcoming electric smart car.

following the unveiling at frieze LA 2024, designboom took a closer look at how the color-changing BMW i5 flow NOSTOKANA was created.

connections: +630

each unit draws inspiration from emergence, featuring a hexahedron-based structure that facilitates integration into larger systems.

connections: 96

brian eno revives his color-changing neon turntable for the second time, on display too at paul stolper gallery in london until march 9th, 2024.

connections: +380

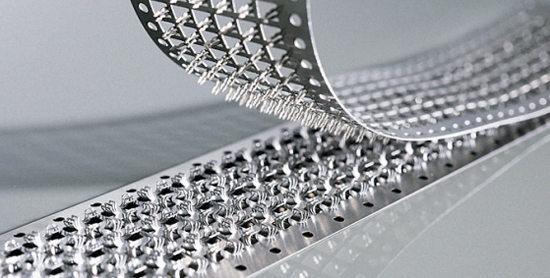

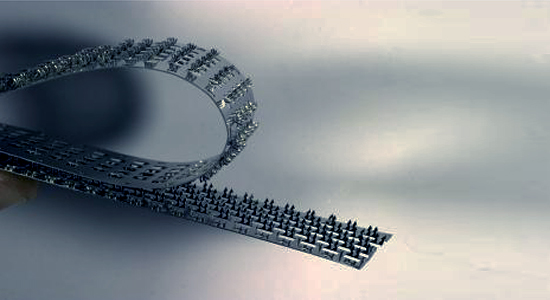

it can be mass-produced photo credit: TUM

it can be mass-produced photo credit: TUM hook HF 1 and loop LF1 combined photo credit: TUM

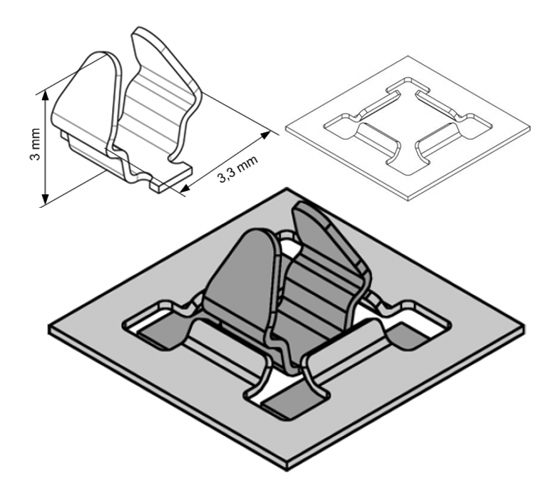

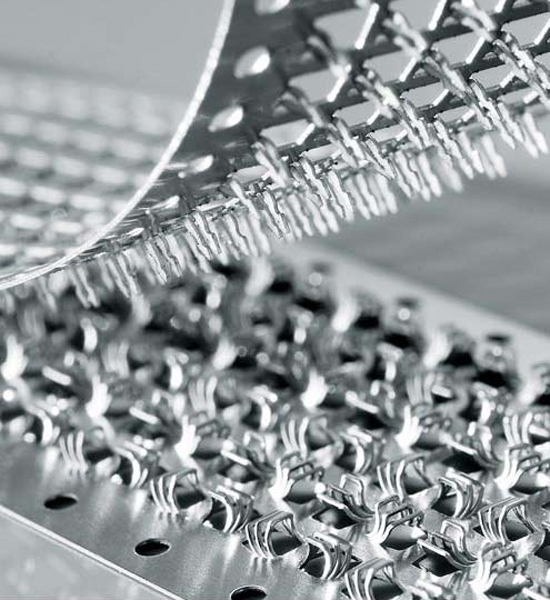

hook HF 1 and loop LF1 combined photo credit: TUM ‘entenkopf” fastener photo credit: TUM

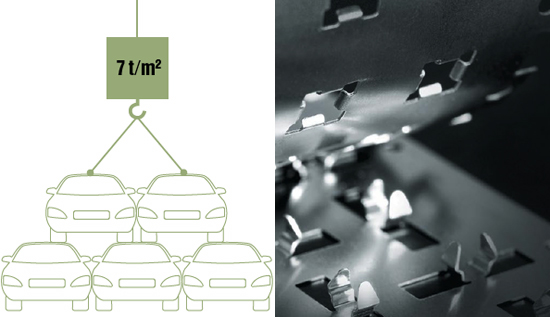

‘entenkopf” fastener photo credit: TUM a hybrid version with synthetic strap photo credit: TUM after testing, the institute settled on two variations: the ‘flamingo’ and ‘entenkopf” (or duck’s head) models. the hook forms of the two systems are vaguely reminiscent of a duck’s head and a flamingo standing on one leg… the entenkopf uses fine steel hooks and loops, while the flamingo uses wider hooks that snap into openings in the tape. depending on the direction of the applied force, this fastener can withstand a load of 7 to 35 newtons per square meter.

a hybrid version with synthetic strap photo credit: TUM after testing, the institute settled on two variations: the ‘flamingo’ and ‘entenkopf” (or duck’s head) models. the hook forms of the two systems are vaguely reminiscent of a duck’s head and a flamingo standing on one leg… the entenkopf uses fine steel hooks and loops, while the flamingo uses wider hooks that snap into openings in the tape. depending on the direction of the applied force, this fastener can withstand a load of 7 to 35 newtons per square meter. ‘entenkopf’ fastener photo credit: TUM

‘entenkopf’ fastener photo credit: TUM close-up of ‘entenkopf’ fastener photo credit: TUM

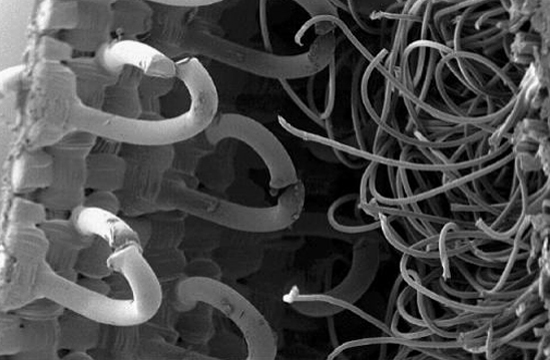

close-up of ‘entenkopf’ fastener photo credit: TUM up and close on velcro® more than 60 years ago, the swiss engineer and inventor

up and close on velcro® more than 60 years ago, the swiss engineer and inventor