KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

PRODUCT LIBRARY

BMW releases the upgraded vision neue klasse X, with a series of new technologies and materials especially tailored for the upcoming electric smart car.

following the unveiling at frieze LA 2024, designboom took a closer look at how the color-changing BMW i5 flow NOSTOKANA was created.

connections: +630

each unit draws inspiration from emergence, featuring a hexahedron-based structure that facilitates integration into larger systems.

connections: 96

brian eno revives his color-changing neon turntable for the second time, on display too at paul stolper gallery in london until march 9th, 2024.

connections: +380

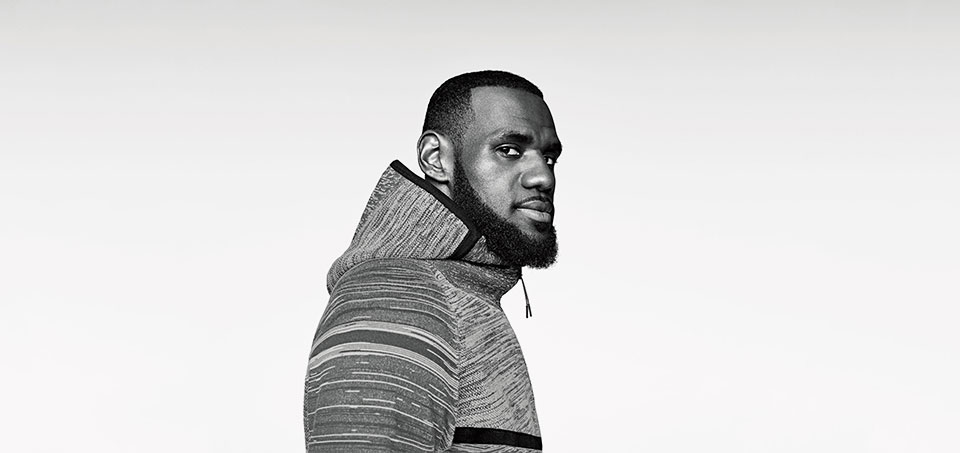

tennis player maria sharapova in the ‘tech knit’ sweater

tennis player maria sharapova in the ‘tech knit’ sweater the collection includes matching pants

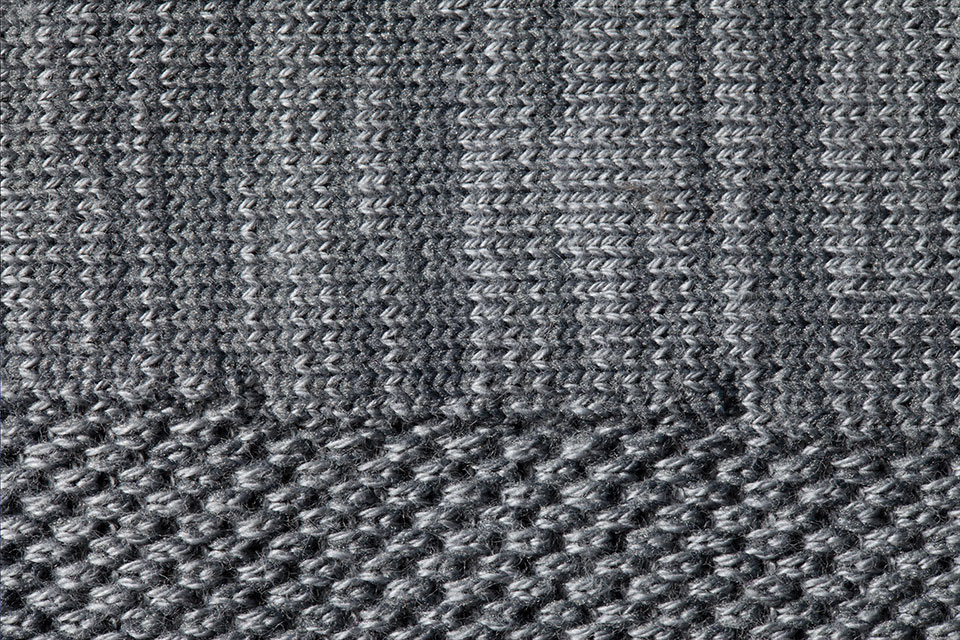

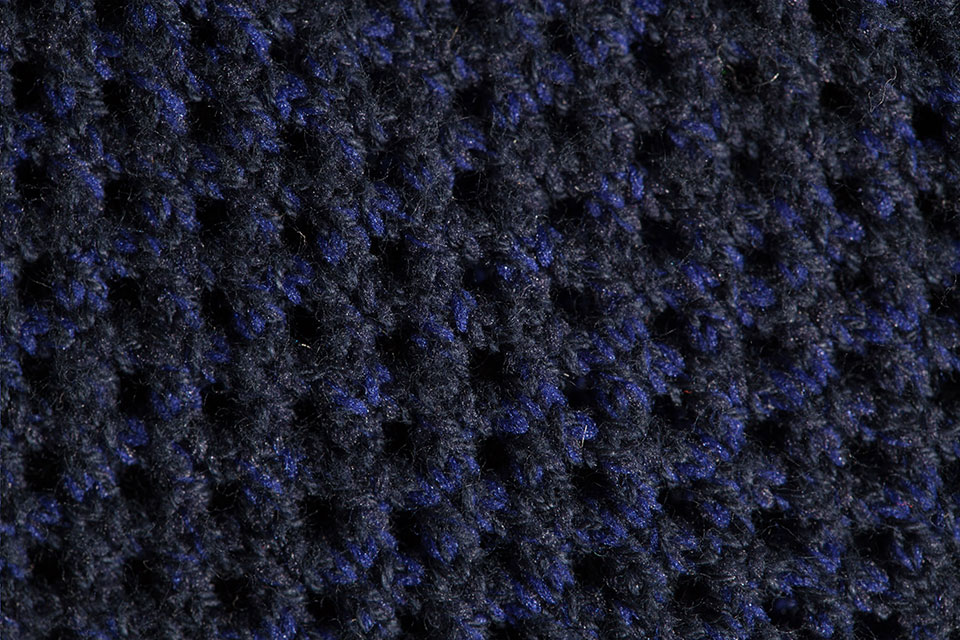

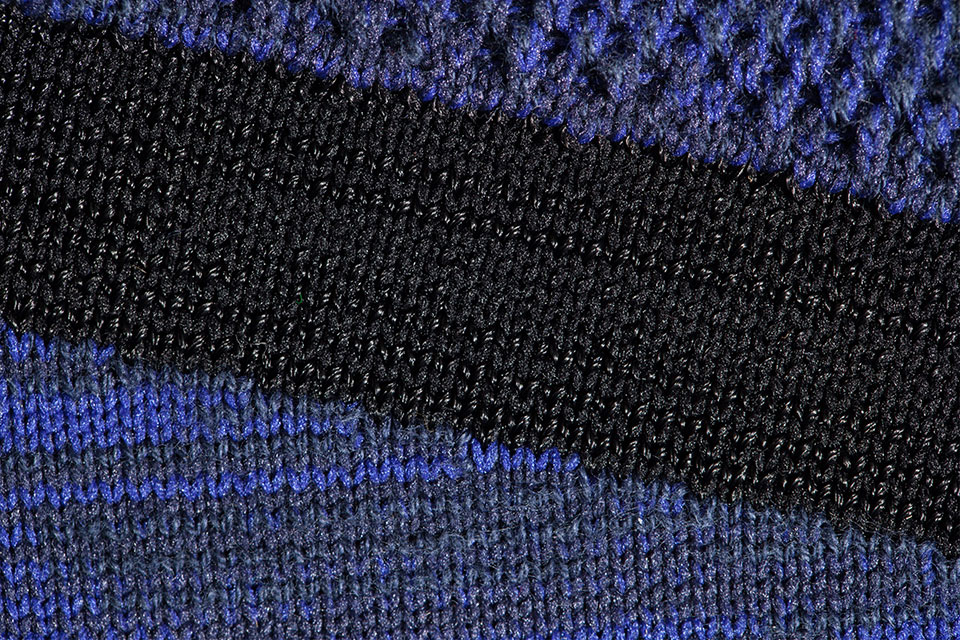

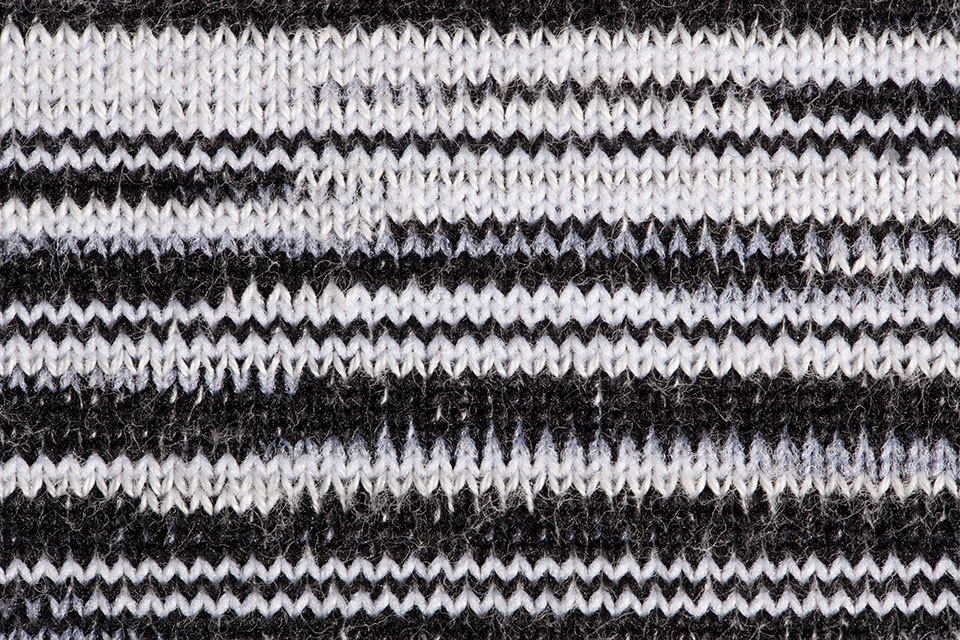

the collection includes matching pants the various engineering knits

the various engineering knits  mrs. jessica lomax at NIKE

mrs. jessica lomax at NIKE the ‘tech knit’ team (left to right): linda brown, senior material developer, tim-campbell stephen, knit director, jessica lomax and rhiannon taylor, senior technical developer

the ‘tech knit’ team (left to right): linda brown, senior material developer, tim-campbell stephen, knit director, jessica lomax and rhiannon taylor, senior technical developer the collection sketches

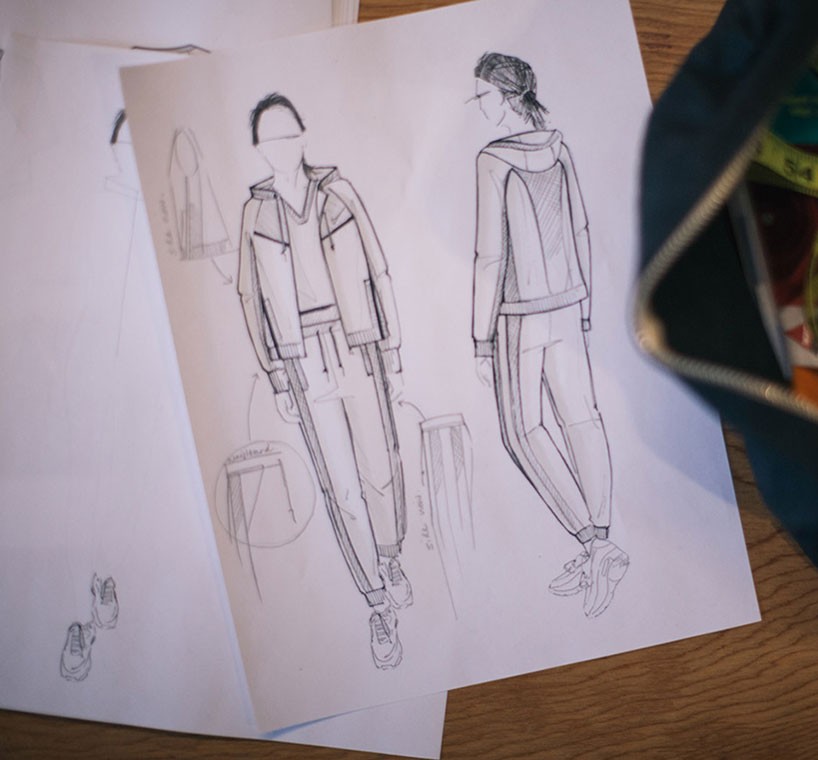

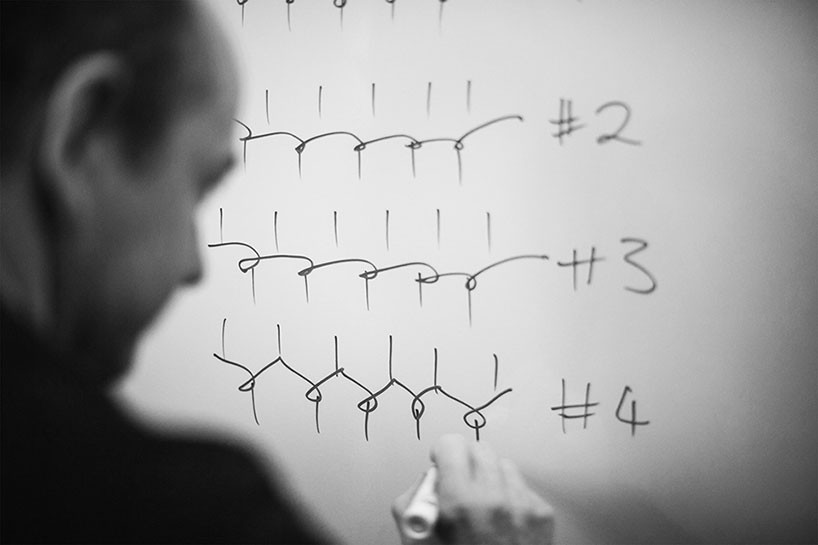

the collection sketches drafts to the stitch count

drafts to the stitch count the team translates sketches to garment with quick samples

the team translates sketches to garment with quick samples the design process is a conversation about yarn details

the design process is a conversation about yarn details  the first prototypes are hand made in the lab

the first prototypes are hand made in the lab  yarn samples

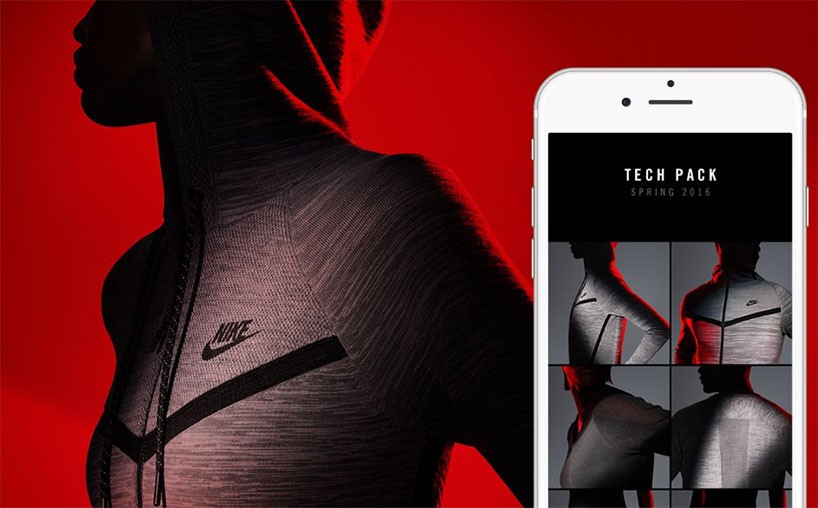

yarn samples  the NIKE ‘tech kit’ is available through the sportswear app

the NIKE ‘tech kit’ is available through the sportswear app