KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

PRODUCT LIBRARY

the apartments shift positions from floor to floor, varying between 90 sqm and 110 sqm.

the house is clad in a rusted metal skin, while the interiors evoke a unified color palette of sand and terracotta.

designing this colorful bogotá school, heatherwick studio takes influence from colombia's indigenous basket weaving.

read our interview with the japanese artist as she takes us on a visual tour of her first architectural endeavor, which she describes as 'a space of contemplation'.

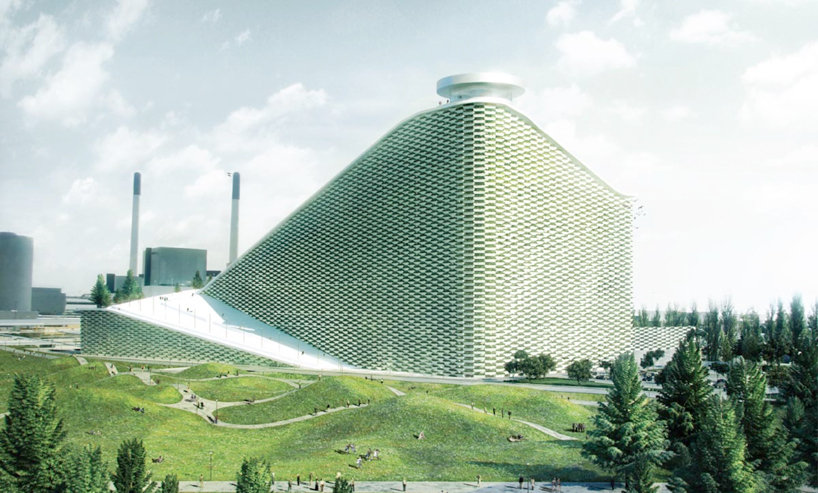

in context

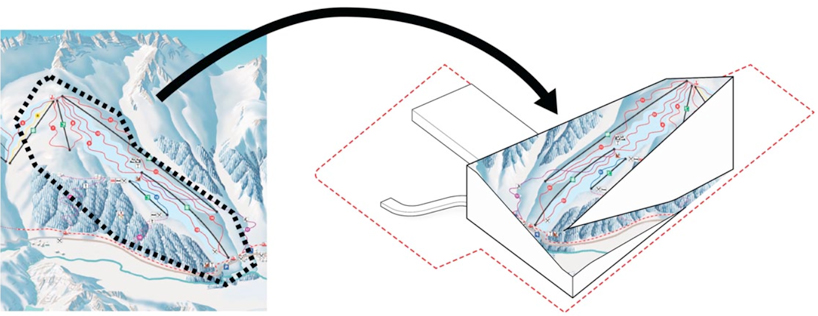

in context ski slope

ski slope

interior atrium space

interior atrium space office level

office level exterior green wall – detail

exterior green wall – detail

at night

at night projected laser light on smoke ring illustrating, in pie chart form, the quota of fossil CO2

projected laser light on smoke ring illustrating, in pie chart form, the quota of fossil CO2

study on waste-to-energy plant in denmark

study on waste-to-energy plant in denmark site map

site map rendered fly by

rendered fly by (upper left) a skin is wrapped around the factory’s internal volumes which was largely determined by engineering and technical criteria (upper right) the building is raised in one corner to accommodate the height of the smokestack (lower left) one side of the envelope is expanded to create an administrative and visitor center (lower right) the corner closest to the street is lowered to allow for public connection

(upper left) a skin is wrapped around the factory’s internal volumes which was largely determined by engineering and technical criteria (upper right) the building is raised in one corner to accommodate the height of the smokestack (lower left) one side of the envelope is expanded to create an administrative and visitor center (lower right) the corner closest to the street is lowered to allow for public connection the roof of the factory is turned into an artificial ski slope

the roof of the factory is turned into an artificial ski slope access to the ski slope is provided by an elevator adjacent to the smoke stack

access to the ski slope is provided by an elevator adjacent to the smoke stack elevation – model

elevation – model view from the water

view from the water open ‘roof lights’ in the slope offer views into the factory

open ‘roof lights’ in the slope offer views into the factory ski slope

ski slope mechanisms for smoke ring

mechanisms for smoke ring smoke ring

smoke ring