KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

each chair reflects an individual child’s input and imagination.

connections: +910

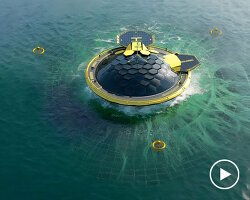

the spiral structure follows principles of fluid dynamics and thermodynamics to optimize heat distribution.

connections: 94

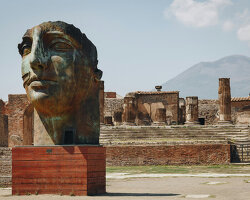

from 3D printed coral reefs to eggshell composite butterfly nests, designboom looks back at the top 10 social impact stories that defined 2025.

connections: 22

amid the rush of a hyper-accelerated world, the hue stands in for a blank canvas.

connections: 45