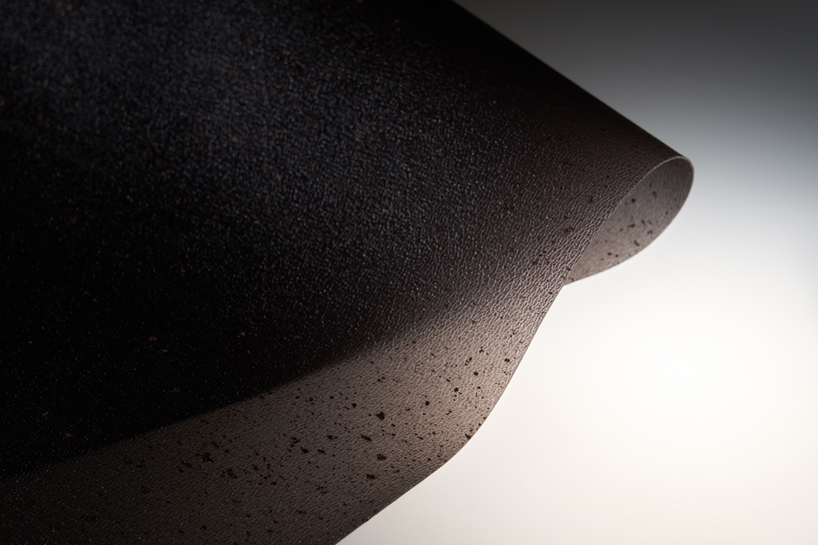

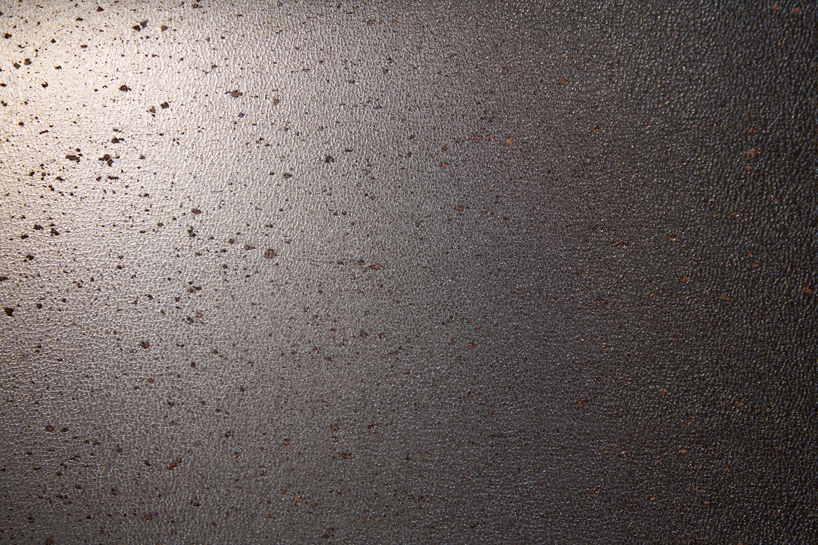

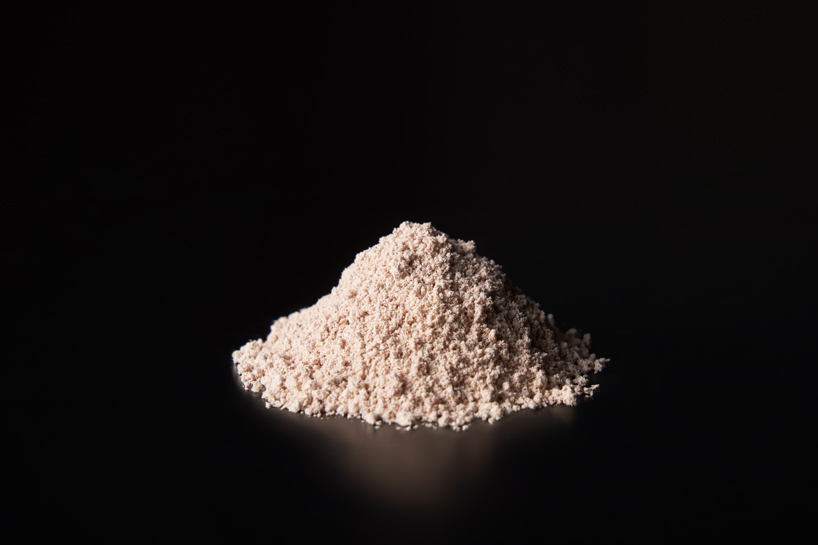

an embossed leather-grain finish enhances the tactile quality

OBRO maintains PVC’s durability, water resistance, and light weight

KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

each chair reflects an individual child’s input and imagination.

connections: +910

the spiral structure follows principles of fluid dynamics and thermodynamics to optimize heat distribution.

connections: 94

from 3D printed coral reefs to eggshell composite butterfly nests, designboom looks back at the top 10 social impact stories that defined 2025.

connections: 23

amid the rush of a hyper-accelerated world, the hue stands in for a blank canvas.

connections: 45