CORNCRETL: A Bio-Based Construction Material from Corn Waste

MANUFACTURA developed CORNCRETL as a bio-based construction material that combines corn byproducts, recycled nejayote, and lime-based aggregates to reduce carbon emissions and introduce circular economy principles into the building industry.

Mexico’s construction sector faces significant environmental and social challenges. The widespread use of carbon-intensive materials has positioned the industry as a major contributor to national CO₂ emissions. At the same time, construction labor conditions remain unstable, with limited access to technical training and high occupational risk. CORNCRETL, developed by MANUFACTURA, proposes a circular material strategy that addresses both environmental impact and production models within the building industry.

CORNCRETL is a bio-based construction material derived from limestone aggregates, corn residues, and recycled nejayote, the calcium-rich wastewater produced during the nixtamalization of corn. The research combines references to pre-Hispanic Mayan construction techniques with robotic 3D printing technologies. Compared to conventional concrete, the material achieves up to a 70 percent reduction in carbon emissions while operating within a circular economy framework.

all images by Dinorah Schulte

MANUFACTURA links Corn Byproducts and Lime Construction

Corn has shaped Mexican society for more than 7,000 years, influencing agricultural systems, settlement patterns, and cultural identity. Archaeological findings in Tehuacán, Puebla, trace its early domestication, and numerous Mesoamerican civilizations integrated corn into their economic and spiritual structures. Today, Mexico remains one of the world’s leading corn producers. However, food waste represents a significant issue, with approximately 38 percent of production lost annually. Tortillas account for nearly 30 percent of this waste. The valorization of corn byproducts, including nejayote, presents both environmental and economic opportunities.

Traditionally discarded, nejayote contains calcium compounds and organic residues that can be reprocessed into construction inputs. CORNCRETL integrates these residues with Geocalce T, a mineral-based aggregate composed of natural hydraulic lime (NHL 3.5), geobinders, river silica sand, dolomitic limestone, and Carrara marble powder. This formulation establishes a dialogue between Mexican agricultural byproducts and Italian mineral materials, reflecting cross-cultural collaboration in material development.

Lime-based construction has historical precedent in Mesoamerica. Known as Sak-Kaab (‘White Earth’) in Mayan culture, lime mixtures such as sascab were valued for breathability, durability, and environmental compatibility. CORNCRETL by Mexico-based design practice MANUFACTURA reinterprets these properties through contemporary fabrication. Unlike Portland cement, lime-based systems harden at room temperature and require lower calcination temperatures, reducing energy consumption and greenhouse gas emissions. Lime materials also provide humidity regulation and self-healing characteristics for minor surface cracks.

CORNCRETL is a bio-based construction material developed by MANUFACTURA

Robotic 3D Printing utilizes Corn-Based Lime Composites

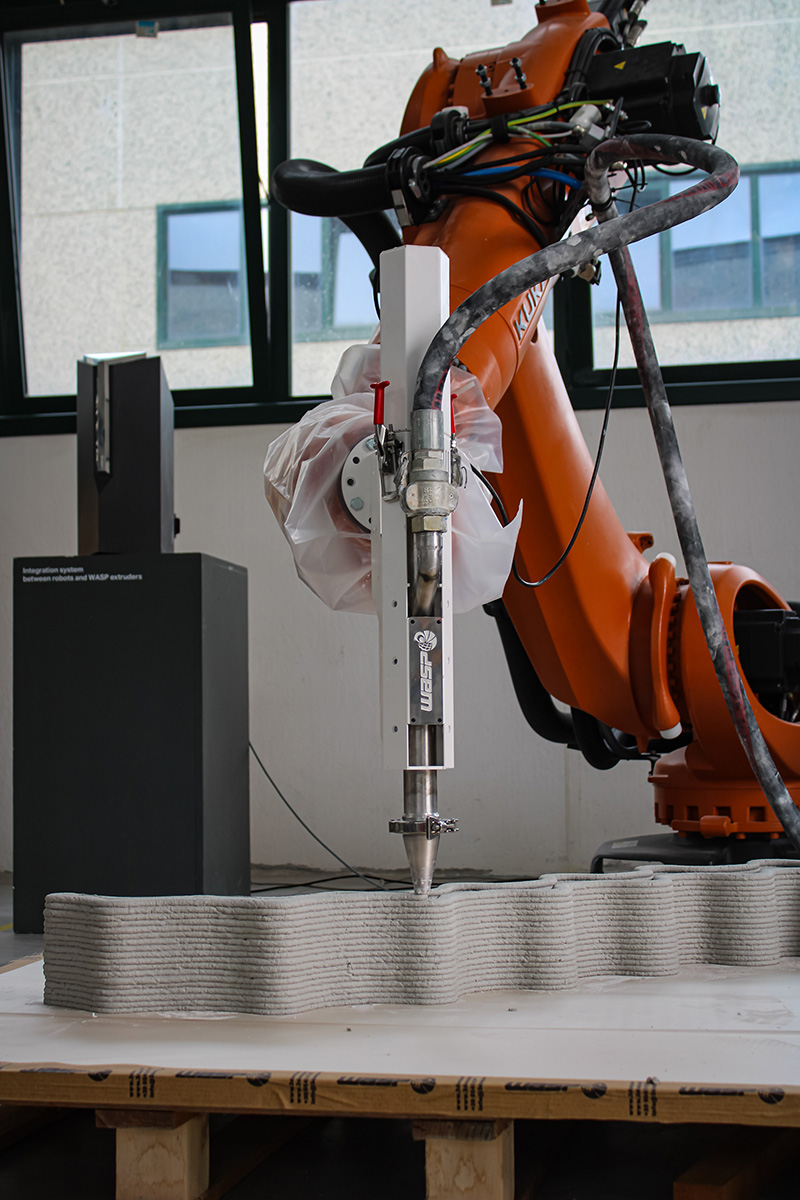

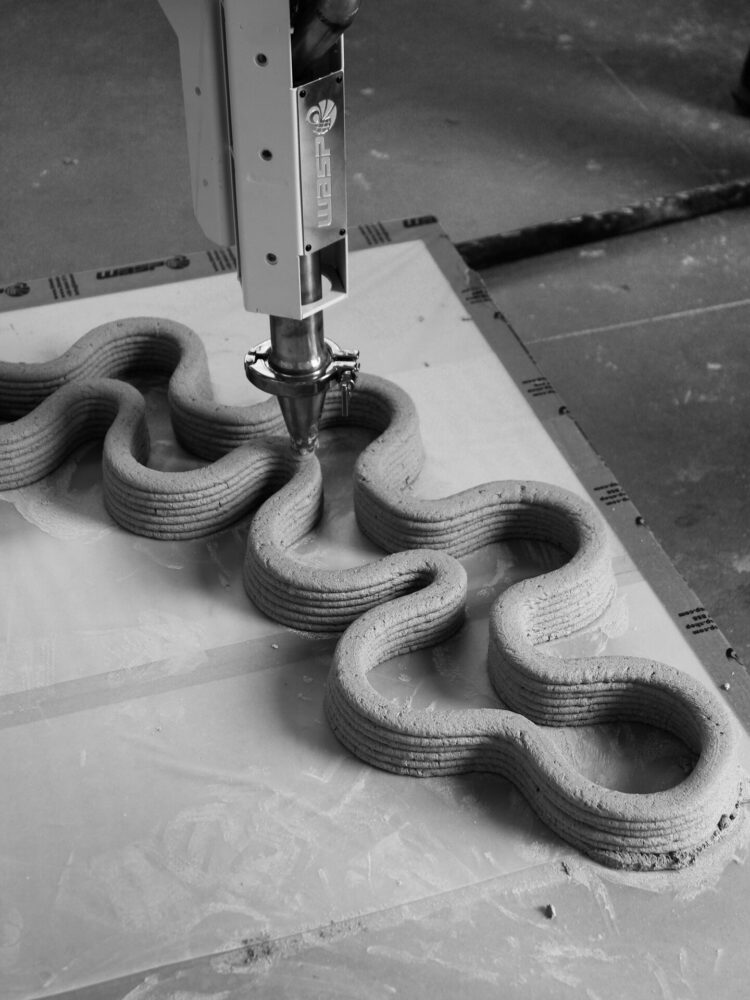

The fabrication process was optimized for robotic 3D printing. Nixtamal waste was collected, dried, shredded, and pulverized to achieve a consistent particle size suitable for extrusion. The material was then blended with mineral aggregates and organic binders to produce a printable mixture. Printability tests were conducted using a WASP Concrete HD Continuous Feeding System integrated with a KUKA robotic arm. Three wall prototypes were printed at varying scales and cured at room temperature for two to three days.

Additive manufacturing eliminates the need for conventional formwork, reducing material waste by up to 90 percent while enabling geometric precision. During the WASP Residency 2025 in Massa Lombarda, Italy, research focused on refining the mix and testing scalability for architectural applications. Structural assessments evaluated compressive performance and material usage per linear meter. Modular wall panels measuring 40 cm, 60 cm, and 80 cm in height were developed as potential components for lightweight, low-cost housing systems. The wall geometries referenced terrazzo motifs from Rimini, demonstrating the material’s capacity for pattern, curvature, and non-rectilinear forms. By combining agricultural waste streams, lime-based mineral systems, and robotic fabrication, CORNCRETL positions bio-based construction as both a technical and cultural proposition.

The project frames construction as a site of material recovery and technological adaptation. Through the integration of ancestral lime knowledge, corn byproducts, and digital manufacturing, CORNCRETL proposes an alternative pathway for sustainable building practices in Mexico, emphasizing reduced emissions, circular resource flows, and scalable housing applications.

the fabrication process was optimized for robotic 3D printing

the mixture incorporates natural hydraulic lime, silica sand, dolomitic limestone, and marble powder

CORNCRETL integrates limestone aggregates with agricultural waste streams

the material reduces carbon emissions by up to 70 percent compared to conventional concrete

CORNCRETL proposes a circular economy model for the building industry

additive manufacturing reduces material waste by eliminating formwork

modular panels were developed for lightweight, low-cost housing applications

the material combines corn residues, recycled nejayote, and lime-based aggregates

corn has shaped Mexican agriculture and settlement patterns for over 7,000 years

the valorization of corn byproducts, including nejayote, presents both environmental and economic opportunities

CORNCRETL combines agricultural byproducts, lime chemistry, and digital fabrication into a scalable construction system

project info:

name: CORNCRETL

designer: MANUFACTURA | @manufacturamx

lead designer: Dinorah Schulte

project director: Edurne Morales

senior computational designer, 3D printing development: Andrea Menardo / Zeitgeistructures

structural engineer: Jorge Armando / TAKO KWEEN + TLAXCALLI

material donator: WASP 3D Industrial Partners

photographer, videographer: Dinorah Schulte, WASP 3D

designboom has received this project from our DIY submissions feature, where we welcome our readers to submit their own work for publication. see more project submissions from our readers here.

edited by: christina vergopoulou | designboom