KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

PRODUCT LIBRARY

the minimalist gallery space gently curves at all corners and expands over three floors.

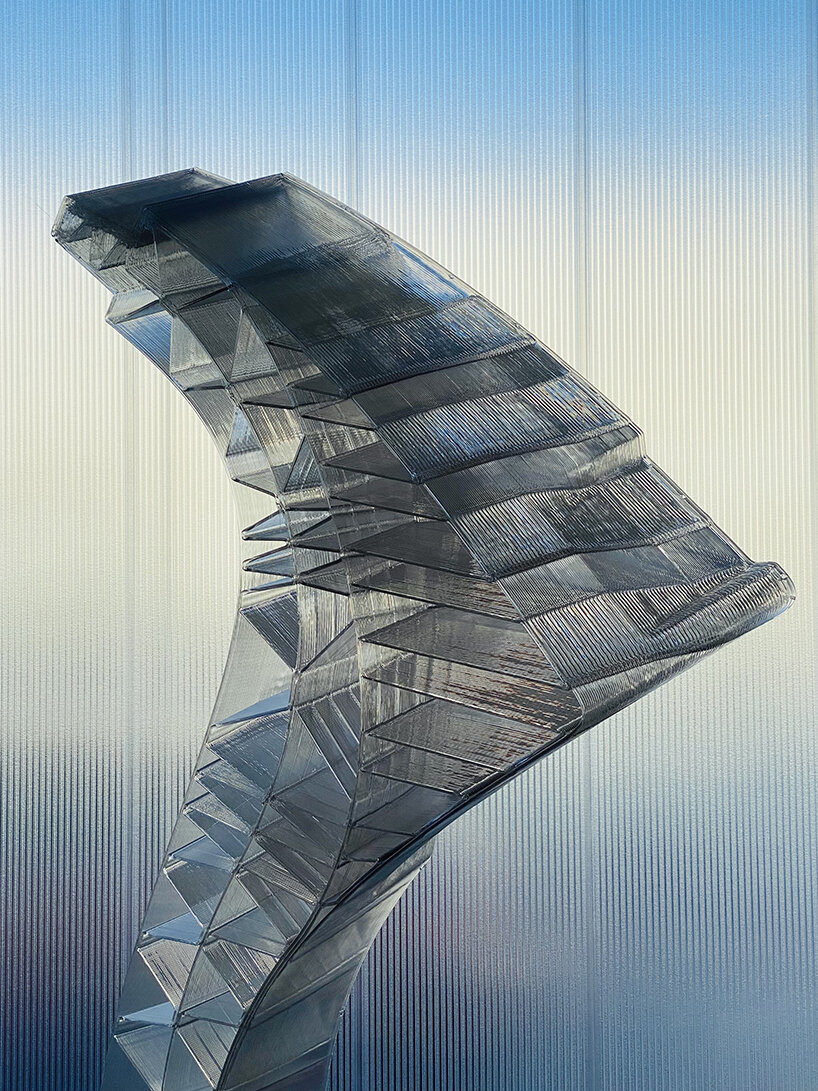

kengo kuma's qatar pavilion draws inspiration from qatari dhow boat construction and japan's heritage of wood joinery.

connections: +730

the home is designed as a single, monolithic volume folded into two halves, its distinct facades framing scenic lake views.

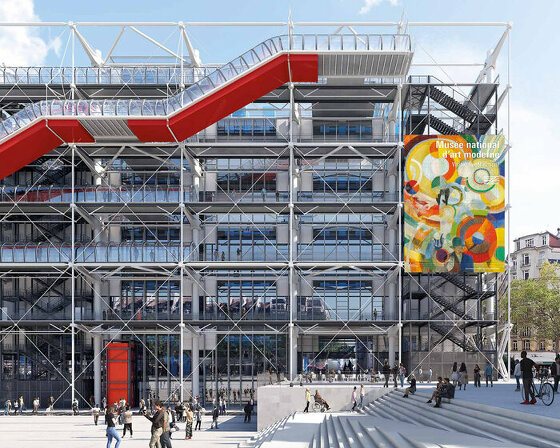

the winning proposal, revitalizing the structure in line with its founding principles, was unveiled during a press conference today, june 20th.