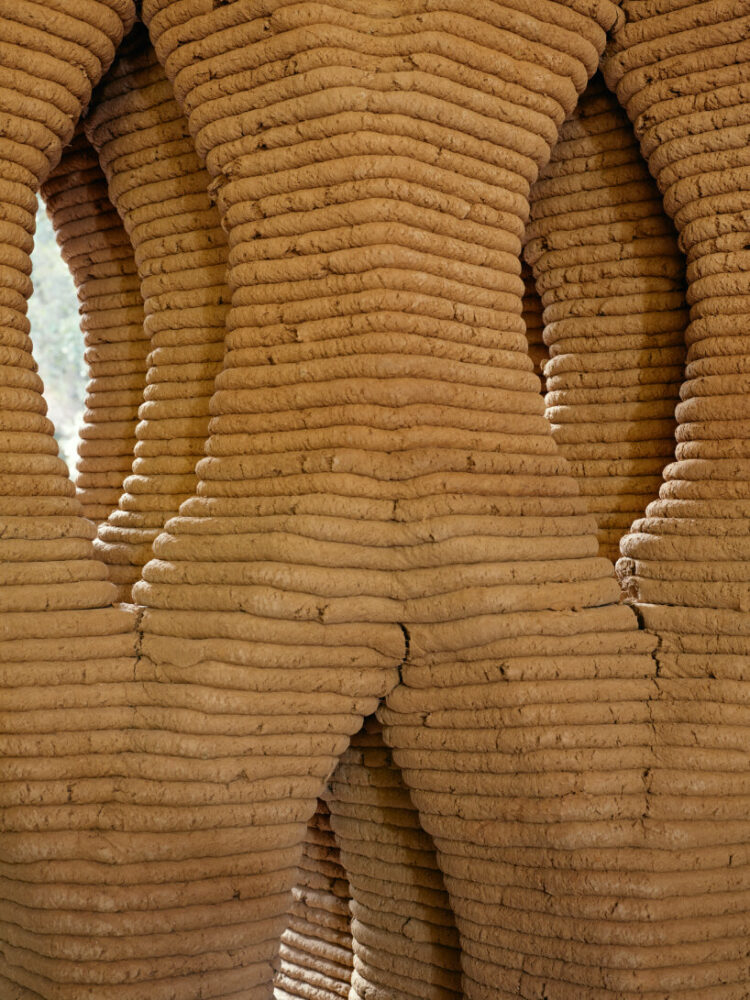

IAAC 3D-printed prototype building in Spain | photo © Gregori Civera

IAAC 3D-printed prototype building in Spain | photo © Gregori Civera

KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

PRODUCT LIBRARY

with its mountain-like rooftop clad in a ceramic skin, UCCA Clay is a sculptural landmark for the city.

charlotte skene catling tells designboom about her visions for reinventing the aaltos' first industrial structure into a building designed for people.

'refuge de barroude' will rise organically with its sweeping green roof and will bring modern amenities for pyrenees hikers.

spanning two floors and a loft, the stitled design gave room for a horizontal expanse at ground level, incorporating a green area while preserving the natural slope.