this year, the ROB|ARCH conference returns to explore how robotic fabrication impacts the fields of architecture, art, and design. hosted by the swiss national centre of competence in research (NCCR) digital fabrication and ETH zurich, the event examines how the advent of robotics in the creative and construction industries has led to a revolution that has not just changed how things are designed and made, but also the broader cultural, political, and economic landscape. under the theme ‘radical cross-disciplinarity’, this year’s conference, which takes place in zurich, switzerland from september 10-15, 2018, will consider topics and issues such as autonomous control systems, computerized materials and structures, and on-site and cooperative robotics.

designboom, an official media partner of ROB|ARCH 2018, spoke with architect and conference chair fabio gramazio who discussed the possibilities of robotic fabrication and what attendees to this year’s event can expect to discover. read the interview in full below.

the fabrication of the sequential roof for ETH zurich’s arch_tec_lab building

image © gramazio kohler research, ETH zurich

designboom (DB): can you recall when you first became interested in the possibilities of robotic fabrication?

fabio gramazio (FG): this was a very long time ago, at the end of the 90s, when large CNC routers became available in the industry, and some architects, for example greg lynn, started experimenting with them.

the finished sequential roof of the arch_tec_lab building at ETH zurich

image © gramazio kohler research, ETH zurich

DB: how have you seen the architecture industry change over the years between then and now?

FG: some of the industries, for example the timber industry, have experienced a significant change in the way they produce; fully embracing what digital technologies have to offer, both at the level of design software as well as CNC machinery allowing for the efficient production of very complex parts. right now, the NCCR digital fabrication is looking into how to extend the digital chain towards the robotic assembly of parts. a good example for this is how the swiss company ERNE AG holzbau built the timber roof for the unique arch_tec_lab building at ETH zurich.

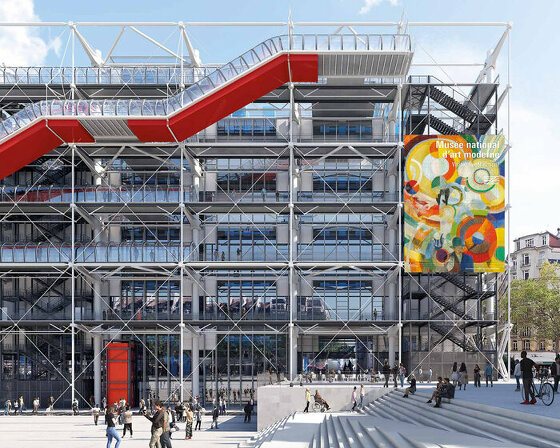

gantenbein vineyard façade, fläsch, switzerland

image © ralph feiner

DB: can you identify particular landmark projects that signify milestones in the development of robotic fabrication techniques?

FG: in the context of the work done at ETH zurich we could mention the brick façades of the winery gantenbein in fläsch from 2006 as well as the already mentioned timber roof for the arch_tec_lab at ETH zurich, which was realized in 2016. the next significant step in this direction is the currently ongoing construction of the DFAB HOUSE project which will be inaugurated early next year on the NEST building of empa and eawag in dübendorf, switzerland. here several digital building technologies which have been developed in the interdisciplinary context of the NCCR digital fabrication are implemented for the first time at real scale.

the smart slab being installed at the DFAB HOUSE | read more about the project on designboom here

image © NCCR digital fabrication / michael lyrenmann

DB: what do you consider to be the field’s most interesting aspects/potential?

FG: being able to translate data into physical material, and thus into architecture, allows us to materialize the digital. this new condition in architecture, which we described as ‘digital materiality’ in our book published with lars müller in 2008, brings together these two realities — the digital and the material — which have been understood as separate. digital materiality allows the architect to inform material, to reconsider existing and invent new constructive systems, and to focus on the design processes instead of geometries. furthermore digital materiality holds a great potential for making architecture more haptic and sensual.

the smart slab segments being placed piece by piece on the 12cm wide mesh mould wall

image © digital building technologies group (DBT), ETH zurich / tom mundy

DB: can you explain your role as conference chair of ROB|ARCH 2018?

FG: our role as conference chairs and hosts of ROB|ARCH 2018 is to coordinate the organization of the conference as well as to overview and support the work of the scientific chairs.

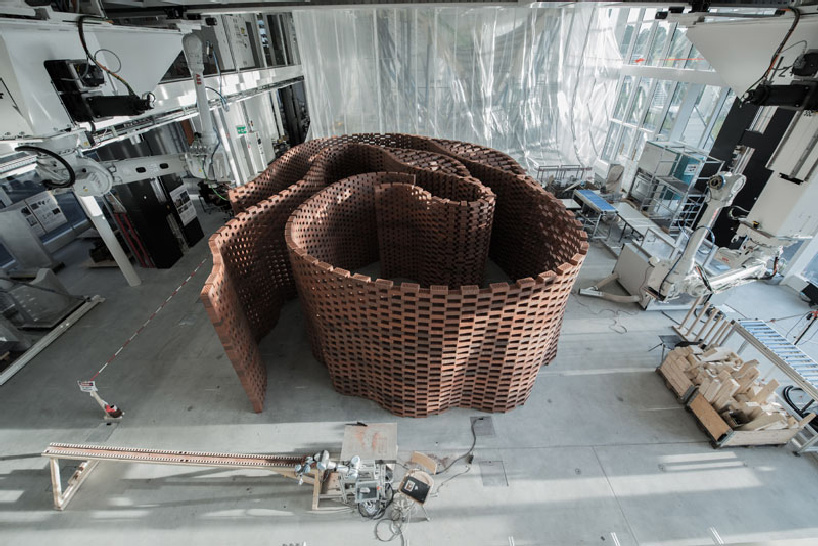

brick labyrinth constructed by students of the master of advanced studies ETH in architecture and digital fabrication in the robotic fabrication laboratory at ETH zurich

image © gramazio kohler research, ETH zurich

DB: can you expand on the event’s ‘radical cross-disciplinarity’ theme?

FG: when architects do not only need to work in close collaboration with structural engineers, but with chemists, material scientists, electrical and mechanical engineers as well as with roboticists, this has an impact on the way we understand our profession. it brings up completely novel challenges addressing established workflows, languages, education and even the very concept of authorship.

robotic assembly of spatial timber modules for the DFAB HOUSE in ETH zurich’s robotic fabrication laboratory

image © NCCR digital fabrication / roman keller

DB: ROB|ARCH’s workshops seem particularly interesting. what can guests expect to experience when taking part?

FG: participants will learn basic skills at using digital technologies such as robots and 3D printers for architecture, art and design. the majority of the workshops will take place in the unique context of the robotic fabrication laboratory at ETH zurich. at the moment, this is the world’s biggest robotic laboratory in the field of architecture. the robotic hall will be full of different workshops, so participants can expect to get insight into various fabrication methods that will be taught by researchers from different international academic institutions.

fabio gramazio is one of the two conference chairs of ROB|ARCH 2018. the second conference chair is matthias kohler. together they hold the chair of architecture and digital fabrication at ETH zurich.

image © gramazio kohler research, ETH zurich

DB: what do you hope visitors take away from the conference? what do you hope that it achieves?

FG: the scope of the conference is to provide a platform for the people from academia as well as from industry, working around these topics, to meet in person and to exchange relevant state of the art information. beyond that, the conference is also offering a variety of social events where people can get to know each other in a more informal context.

DB: do more students need to be made aware of the possibilities of robotic fabrication?

FG: definitely!

ROB|ARCH is an event that explores robotic fabrication in architecture, art, and design. taking place between september 10-15, the 2018 event is hosted at ETH zurich, switzerland, by the NCCR digital fabrication, ETH zurich and the association for robots in architecture under the theme ‘radical cross-disciplinarity’. designboom is an official media partner of ROB|ARCH 2018. more information and registration: www.robarch2018.org. you can also follow the event on instagram: @robarch2018

the ROB|ARCH 2018 conference series is a collaborative effort between the hosting universities, industry partners and the association for robots in architecture. initiated by the association for robots in architecture in 2012, past conferences were hosted by the technical university vienna (2012), the university of michigan’s taubman college of architecture and urban planning (2014), and the university of sydney’s faculty of architecture, design and planning.

architecture interviews (267)

gramazio kohler (12)

ROBARCH 2018 (2)

robots (535)

PRODUCT LIBRARY

a diverse digital database that acts as a valuable guide in gaining insight and information about a product directly from the manufacturer, and serves as a rich reference point in developing a project or scheme.