KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

PRODUCT LIBRARY

the minimalist gallery space gently curves at all corners and expands over three floors.

kengo kuma's qatar pavilion draws inspiration from qatari dhow boat construction and japan's heritage of wood joinery.

connections: +730

the home is designed as a single, monolithic volume folded into two halves, its distinct facades framing scenic lake views.

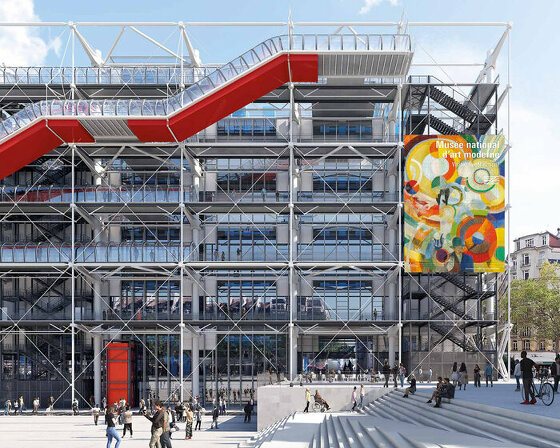

the winning proposal, revitalizing the structure in line with its founding principles, was unveiled during a press conference today, june 20th.

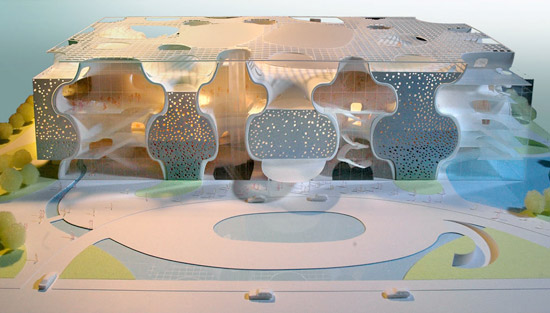

model of the taichung metropolitan opera house

model of the taichung metropolitan opera house drawing of the taichung metropolitan opera house

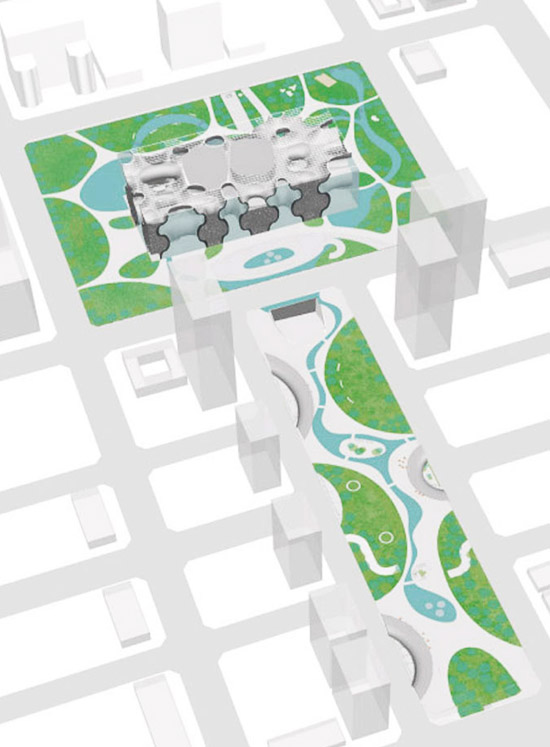

drawing of the taichung metropolitan opera house drawing of the taichung metropolitan opera house

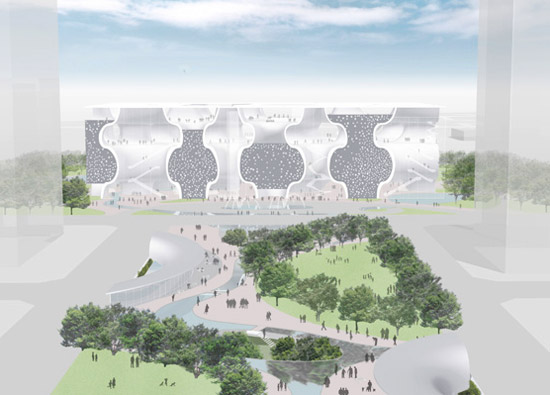

drawing of the taichung metropolitan opera house integrated in the landscape

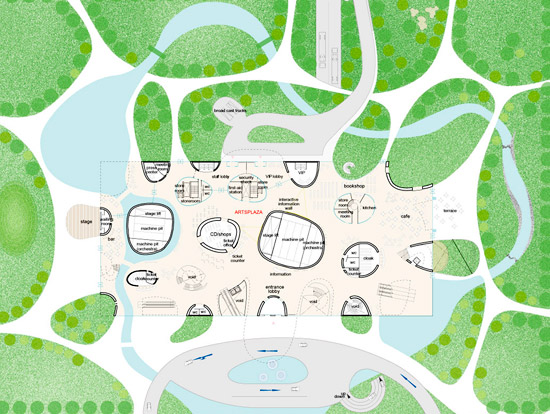

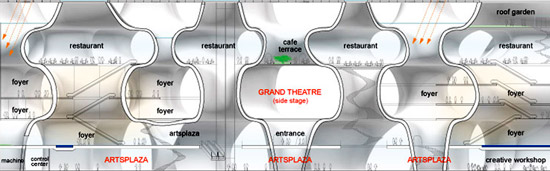

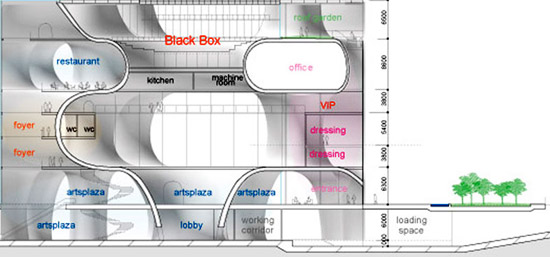

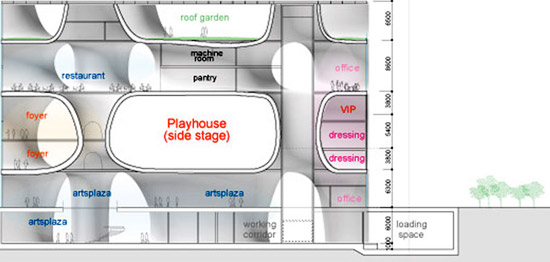

integrated in the landscape spatial organization

spatial organization left: audience circulation, right: VIP and office circulation

left: audience circulation, right: VIP and office circulation ito’s work has been highly concerned with the notions of an all-encompassing, ever expanding space.

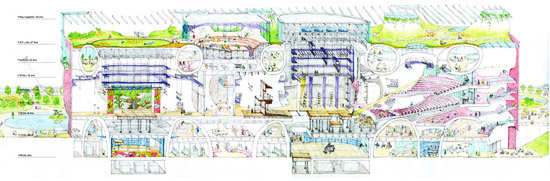

ito’s work has been highly concerned with the notions of an all-encompassing, ever expanding space. a nearly 4m large-scale model. ito made full-scale structural models to simply prove its integrity.

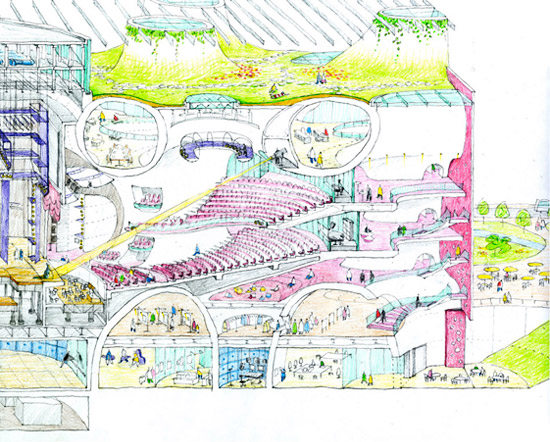

a nearly 4m large-scale model. ito made full-scale structural models to simply prove its integrity. continuous surfaces in an open structure which actively engages its surroundings in all directions and creates great opportunities for artists and visitors, stage and auditorium, interior and exterior.

continuous surfaces in an open structure which actively engages its surroundings in all directions and creates great opportunities for artists and visitors, stage and auditorium, interior and exterior. toyo ito calls this space the ‘sound cave’, a horizontally and vertically continuous network.

toyo ito calls this space the ‘sound cave’, a horizontally and vertically continuous network. toyo ito portrait © designboom

toyo ito portrait © designboom illustration by studio toyo ito

illustration by studio toyo ito part 1

part 1 part 2

part 2 part 3

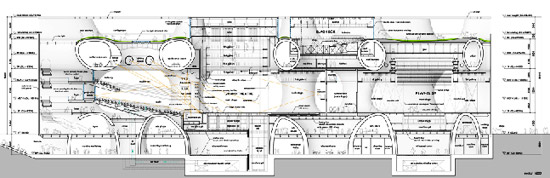

part 3 section drawing

section drawing part 1

part 1 part 2

part 2 part 3

part 3 challenging technique

challenging technique grand theatre

grand theatre black box

black box play house

play house