KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

PRODUCT LIBRARY

the south african artist talks to designboom about the nine-episode film series, available on MUBI from october 18, 2024.

connections: +150

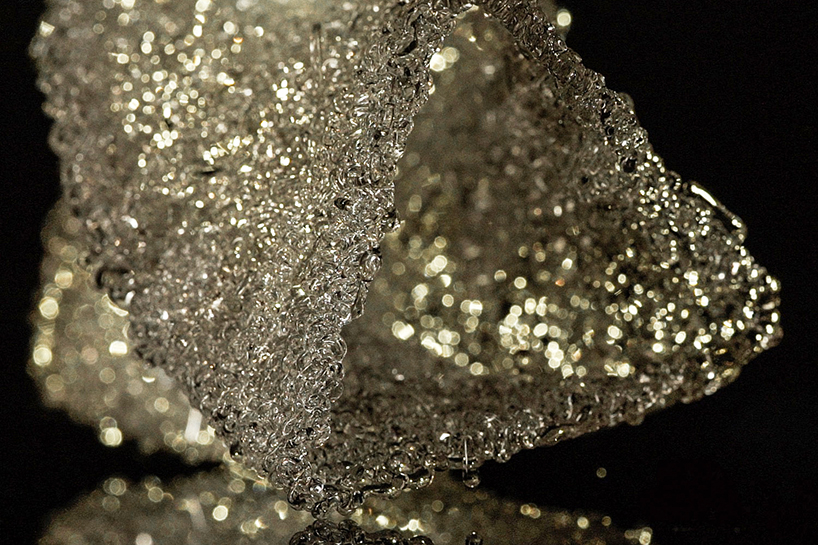

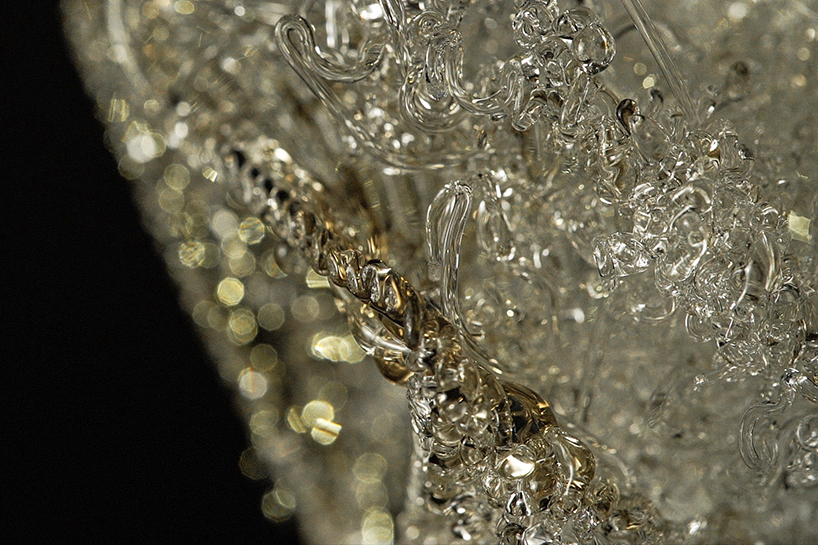

dive into our guide for the must-see highlights of art basel paris and design miami.paris 2024, as well as all other exciting shows in paris.

connections: 13

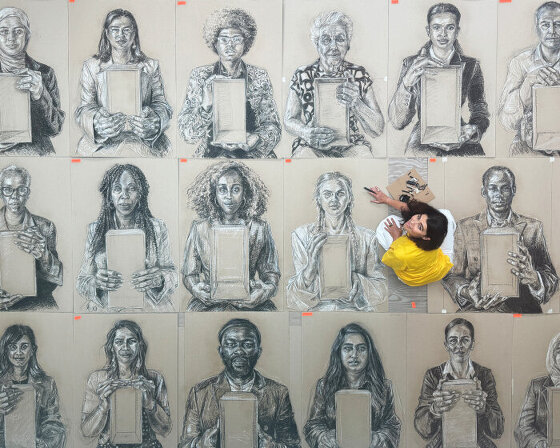

before the unveiling of her recent work, the english artist explores congregation in an interview with designboom and how the 50 portraits of displaced people came to life.

connections: +1420

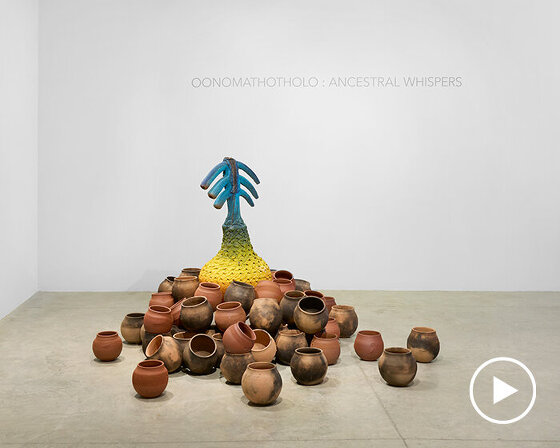

designboom gets a first look of the south african artist's new exhibition, 'oonomathotholo: ancestral whispers', at friedman benda NY.

connections: +250