caesarstone quartz surfaces: a visit inside the factory of ‘engineered stone’ —

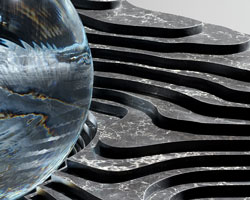

established in 1987 in the kibbutz of sdot yam in israel, caesarstone is a pioneer in the natural quartz surfaces market, foreseeing a technological breakthrough that has resulted in the brand’s signature product. by combining quartz — the second hardest material — with resin, they have achieved a durable, hard and flexible product ideal for harsh environments. through continuous investment and innovation, extensive research and development, highly trained personnel and an advanced market infrastructure, caesarstone has set new standards and trends in the industry for three decades.

designboom visited caesarstone’s factory in israel, where we had a chance to get a behind-the-scenes look at the transformation of quartz into strong, flexible, resistant, and low-maintenance surfaces.

all images of caesarstone quartz surfaces by designboom.

production line of caesarstone quartz surfaces. caesarstone is a publicly traded company that engages in the manufacture and sale of engineered stone surfaces.

caesarstone offers products that are not just stunning but sustainable as well. the long-standing company culture of responsible manufacturing keeps sustainability as one of its pillars. from recycling 97% of the water used in manufacturing, to collecting dust from shipping, handling, production and processing, caesarstone is committed to protecting the environment. all residual waste material is securely stored to prevent environmental leakage and regenerative thermal oxidizer installations are found throughout the plant, improving the surrounding air quality.

the company was founded in 1987 and is headquartered in kibbutz sdot yam in israel

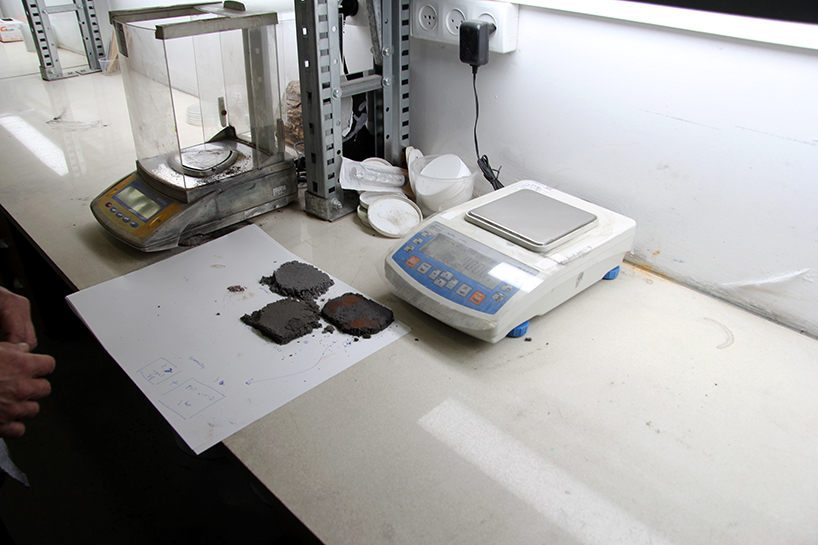

quartz is one of nature’s most abundant minerals and is available in quantities far greater than any other stone. caesarstone has invented innovative ways to put mineral refuse to good use by harvesting from the most common source of quartz — the by-products of other mining industries. by collecting and using them, the company helps eliminate waste. the collected material is crushed, washed, and sifted prior to manufacturing process.

caesarstone quartz surfaces are sold in 50 countries around the world

by developing new technologies and production processes, caesarstone has consistently been at the forefront of innovation, allowing them to create breakthrough designs. through collaborations with world-renowned designers and partners, they have been able to generate new concepts, different textures, finishes and radical designs. while these partnerships have garnered them with many design awards, their purpose have a much more important function; to push boundaries.

caesarstone quartz surfaces are a more affordable alternative to granite surfaces

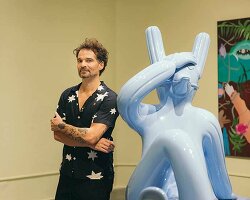

beginning in 2013, the designer collaboration programme has proved caesarstone to be not only a brand with a successful quartz product, but also a visionary leader in the design community. in 2013, caesarstone engaged in its first design collaboration with japanese designer nendo for milan design week 2013. oki sato — nendo’s creative director — created ‘stone garden’ and ‘stone-edge table’, two installations that emphasize caesarstone’s quartz surfaces qualities of strength, durability and design.

common uses include caesarstone quartz surfaces for kitchen countertops, vanity tops, wall-cladding, flooring and quartz sinks…

during milan design week 2014, caesarstone partnered with london-based duo raw edges to create the ‘islands’ installation. the result is a set of modular pieces that generate three-dimensional structures. instead of placing the different objects above, under or next to the surface, they were incorporated into it, turning the surface into the heart and soul of the kitchen.

the company highly invests in innovation, extensive research and development

the following year — milan design week 2015 — philippe malouin offered a unique interpretation of caesarstone’s material through the design of an 8-piece swing set called ‘movement’. the installation presented solid surfaces that became playful objects, and a series of handmade planters that were created via an exploration of fabrication techniques and applications, ranging from the mundane to the more experimental.

highly trained personnel and an advanced market infrastructure sets new standards and trends

2016 saw british designer tom dixon undertake an exploratory collaboration. based on a truly artistic concept and experimentation with the quartz surfaces, the result was the creation of four semi-professional kitchens inspired by water, fire, earth and air presented during milan design week 2016 at rotonda della bessana at the ‘restaurant by caesarstone and tom dixon’ installation.

sustainability sits at caesarstone’s core, making it a priority in the production processes

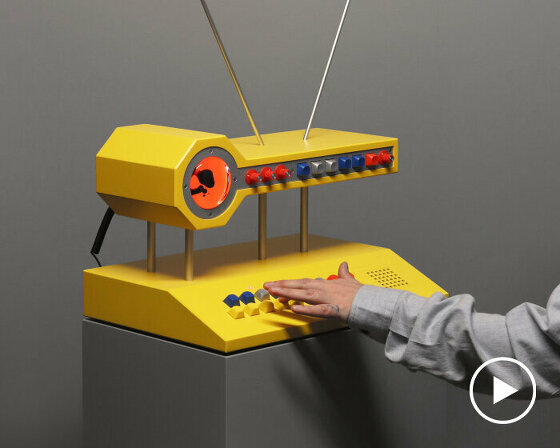

the versatility and flexibility of caesarstone’s premium surfaces was exposed through the imaginative visionary eyes of spanish designer jaime hayon during milan design week 2017. called ‘stone age folk’, the installations utilized high-end stone marquetry techniques, incorporating over 48 colors with metal and glass into the creation of a fantasy world pavilion of multiple forms, patterns and shapes, as well as unique, handmade pieces. by combining creativity, quality and durability, quartz became a strong source of design inspiration for many creatives and caesarstone became a catalyst for this.

97% of the water used in manufacturing is recycled

collecting dust from shipping, handling, production and processing protects the environment

all residual waste material is securely stored to prevent environmental leakage

regenerative thermal oxidizer installations are found throughout the plant, improving the surrounding air quality

caesarstone has invented innovative ways to put mineral refuse to good use

by developing new technologies and production processes, caesarstone has been at the forefront of innovation

the company has collaborated with renowned designers to create installations for design fairs around the world

‘baking’ is how caesarstone defines the company’s material research process that includes many external collaborations with international designers, among them raw edges, nendo, philippe malouin, tom dixon and jaime hayon.

caesarstone (14)

factory visits (28)

jaime hayon (60)

jerusalem design week 2017 (4)

nendo (271)

philippe malouin (16)

tom dixon (53)

PRODUCT LIBRARY

a diverse digital database that acts as a valuable guide in gaining insight and information about a product directly from the manufacturer, and serves as a rich reference point in developing a project or scheme.