KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

PRODUCT LIBRARY

explore the design and architecture of the paris 2024 olympics, as well as the city shows coinciding with the games.

connections: +610

TERRA COSMOS deciphers new desires and expectations of consumers in search of awe-inspiring experiences through a vision of the future.

connections: 1

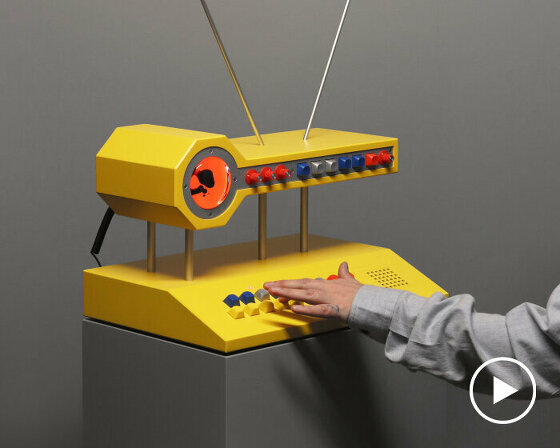

as visitors press the keys, a gooey liquid is brought to life, dancing hypnotically in sync with the chilling tunes.

connections: +250

watch iF Design's panel - power of place - livestreamed and moderated by designboom during NYCxDesign 2024.

connections: 90

‘suple’ occasional table

‘suple’ occasional table 3D printed components

3D printed components potential placement of the components

potential placement of the components legs

legs ‘suple’ connectors are made from aluminium or bronze

‘suple’ connectors are made from aluminium or bronze underside view

underside view technical renderings

technical renderings 3D printed molds are prepared for being cast in silicone

3D printed molds are prepared for being cast in silicone silicone is poured into the moulds to create the negatives of the pieces

silicone is poured into the moulds to create the negatives of the pieces wax is then poured into the mold to form the positives of the ‘suple’ components

wax is then poured into the mold to form the positives of the ‘suple’ components the wax is then covered in a ceramic shell made from a mixture of glue and sand

the wax is then covered in a ceramic shell made from a mixture of glue and sand a casting cone is used to bring the molten liquid metal to the shell

a casting cone is used to bring the molten liquid metal to the shell the set metal pieces are then removed and finished

the set metal pieces are then removed and finished finished ‘suple’ pieces

finished ‘suple’ pieces