KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

PRODUCT LIBRARY

explore the design and architecture of the paris 2024 olympics, as well as the city shows coinciding with the games.

connections: +610

TERRA COSMOS deciphers new desires and expectations of consumers in search of awe-inspiring experiences through a vision of the future.

connections: 1

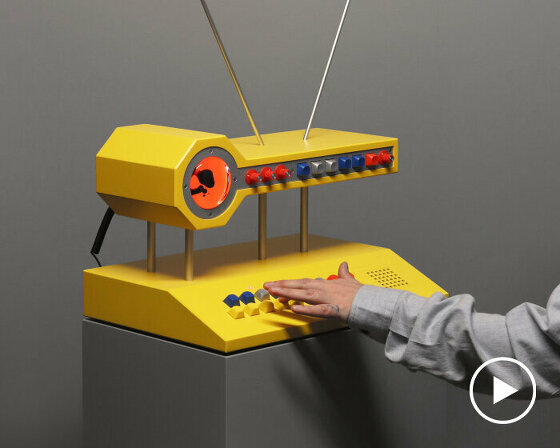

as visitors press the keys, a gooey liquid is brought to life, dancing hypnotically in sync with the chilling tunes.

connections: +250

watch iF Design's panel - power of place - livestreamed and moderated by designboom during NYCxDesign 2024.

connections: 90

floor map of the ‘nuova meccanica’ (‘mechanical workshop’)

floor map of the ‘nuova meccanica’ (‘mechanical workshop’) the entrance opens onto a second-floor balcony, offering a view of the factory floorimage © designboom

the entrance opens onto a second-floor balcony, offering a view of the factory floorimage © designboom automated robots temper cylinder headsimage © designboom

automated robots temper cylinder headsimage © designboom greenspaces both indoors and out temper the metal and machinery of theplant, as part of the ‘formula uomo’ initiative for employee health andcontentmentimage courtesy ferrari

greenspaces both indoors and out temper the metal and machinery of theplant, as part of the ‘formula uomo’ initiative for employee health andcontentmentimage courtesy ferrari a sanitation station runs (front left) while technicians work in the distanceimage © designboom

a sanitation station runs (front left) while technicians work in the distanceimage © designboom image © designboom

image © designboom image © designboom

image © designboom testing of componentsimage © designboom

testing of componentsimage © designboom stacked cylinder headsimage © designboom

stacked cylinder headsimage © designboom gardens surround the building, and trees along the floor’s center offset the technology and high industry of the factoryimage © designboom

gardens surround the building, and trees along the floor’s center offset the technology and high industry of the factoryimage © designboom engine production machines work behind closed wallsimage © designboom

engine production machines work behind closed wallsimage © designboom cylinder headsimage © designboom

cylinder headsimage © designboom a finished engineimage © designboom

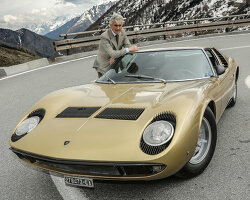

a finished engineimage © designboom ‘166 inter vignale’ (1948) in the show area of of the workshopimage © designboom

‘166 inter vignale’ (1948) in the show area of of the workshopimage © designboom ‘166 inter vignale’ (1948)image © designboom

‘166 inter vignale’ (1948)image © designboom technology like the trigeneration plant evaporative cooler circuit, pictured above in another building on the ferrari campus, are among the ecologically sustainable initiativesferrari has undertaken in recent years – this machine simultaneously produces power, heat, and cooling, reducing carbon emissions by about 40%image courtesy ferrari

technology like the trigeneration plant evaporative cooler circuit, pictured above in another building on the ferrari campus, are among the ecologically sustainable initiativesferrari has undertaken in recent years – this machine simultaneously produces power, heat, and cooling, reducing carbon emissions by about 40%image courtesy ferrari view leaving the buildingimage © designboom

view leaving the buildingimage © designboom