KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

PRODUCT LIBRARY

explore the design and architecture of the paris 2024 olympics, as well as the city shows coinciding with the games.

connections: +610

TERRA COSMOS deciphers new desires and expectations of consumers in search of awe-inspiring experiences through a vision of the future.

connections: 1

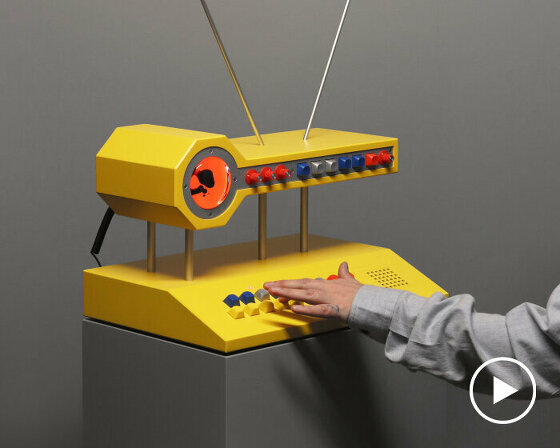

as visitors press the keys, a gooey liquid is brought to life, dancing hypnotically in sync with the chilling tunes.

connections: +250

watch iF Design's panel - power of place - livestreamed and moderated by designboom during NYCxDesign 2024.

connections: 90

the ‘impulsive furnishing unit’ surrounded by the adhoc pieces it createsimage courtesy of the designers

the ‘impulsive furnishing unit’ surrounded by the adhoc pieces it createsimage courtesy of the designers the ‘impulsive furniture unit’image courtesy of the designers

the ‘impulsive furniture unit’image courtesy of the designers top (from left to right): thomas vailly, itay ohaly, robert thiemann, co-founder of FRAME magazine, christian fiebig, jana scholze and marcel wandersbottom: marcel wanders unlocks the suitcase of prize money handcuffed to robert theimann’s hands and presents the award to the winnersimages © designboom

top (from left to right): thomas vailly, itay ohaly, robert thiemann, co-founder of FRAME magazine, christian fiebig, jana scholze and marcel wandersbottom: marcel wanders unlocks the suitcase of prize money handcuffed to robert theimann’s hands and presents the award to the winnersimages © designboom