KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

nik bentel studio scales down the lidl supermarket trolley into a stainless steel, wire-frame handbag dubbed the 'trolley bag.'

connections: +330

as designboom evolves into a creative studio, designboom needs a lab senior editor to manage our branded and organic campaigns.

each chair reflects an individual child’s input and imagination.

connections: +920

the spiral structure follows principles of fluid dynamics and thermodynamics to optimize heat distribution.

connections: 96

the materials which comprise each shoe made in the small factoryimage © designboom

the materials which comprise each shoe made in the small factoryimage © designboom segments of the shoe in varied states of constructionimage © designboom

segments of the shoe in varied states of constructionimage © designboom individual components of the shoeimage © designboom

individual components of the shoeimage © designboom moulding the upper over the toe boardimage © designboom

moulding the upper over the toe boardimage © designboom  pulling the toe and upper into formimage © designboom

pulling the toe and upper into formimage © designboom resting for a moment as the form fits the shape of the mouldimage © designboom

resting for a moment as the form fits the shape of the mouldimage © designboom the completed bootimage © designboom

the completed bootimage © designboom  each shoe is outfitted with the flag of the country that wears the bootimage © designboom

each shoe is outfitted with the flag of the country that wears the bootimage © designboom  the nike GSimage © designboom

the nike GSimage © designboom the underside of nike’s newest bootimage © designboom

the underside of nike’s newest bootimage © designboom the boot ready for packagingimage © designboom

the boot ready for packagingimage © designboom graphic breakdown of the boot’s componentsimage © designboom

graphic breakdown of the boot’s componentsimage © designboom a view of the nike GS signage within the small factoryimage © designboom

a view of the nike GS signage within the small factoryimage © designboom the station where rubber cement is applied to the bootimage © designboom

the station where rubber cement is applied to the bootimage © designboom an additional view of the italian nike production facilityimage © designboom

an additional view of the italian nike production facilityimage © designboom boot-shapers and half completed shoes wait on a shelving systemimage © designboom

boot-shapers and half completed shoes wait on a shelving systemimage © designboom nike’s montebelluna factoryimage © designboom

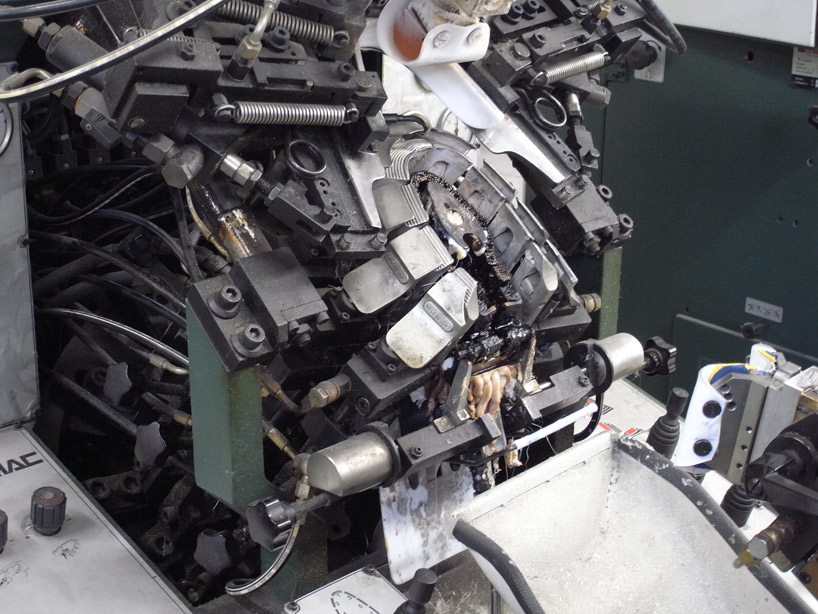

nike’s montebelluna factoryimage © designboom detailed perspective of a machine in the manufacturing line for the nike GS bootimage © designboom

detailed perspective of a machine in the manufacturing line for the nike GS bootimage © designboom moulds for the soul of several nike football shoesimage © designboom

moulds for the soul of several nike football shoesimage © designboom each of the baskets contain a collection of differing plastic components in which each shoe takes its size and general shapeimage © designboom

each of the baskets contain a collection of differing plastic components in which each shoe takes its size and general shapeimage © designboom another perspective picturing the production facilityimage © designboom

another perspective picturing the production facilityimage © designboom industrial sewing machine which embroiders a custom logo, name and country flag onto each shoeimage © designboom

industrial sewing machine which embroiders a custom logo, name and country flag onto each shoeimage © designboom boots packaged and labeled according to the player- display of the boots which nike has created image © designboom

boots packaged and labeled according to the player- display of the boots which nike has created image © designboom several of the high-powered production pieces required to build each of nike’s football bootsimage © designboom

several of the high-powered production pieces required to build each of nike’s football bootsimage © designboom the cozyplant features a level of personalization in the manufacturing line, as many of the machines are decorated with sport or nike related photographsimage © designboom

the cozyplant features a level of personalization in the manufacturing line, as many of the machines are decorated with sport or nike related photographsimage © designboom image © designboom

image © designboom image © designboom

image © designboom image © designboom

image © designboom a workstation for precise additions to each piece of footwearimage © designboom

a workstation for precise additions to each piece of footwearimage © designboom workers who produce the top-quality boots by nike are incredibly attentive while directing these powerful pieces of equipment image © designboom

workers who produce the top-quality boots by nike are incredibly attentive while directing these powerful pieces of equipment image © designboom showcase of boot’s nike produces in the factory’s lobbyimage © designboom

showcase of boot’s nike produces in the factory’s lobbyimage © designboom the nike symbol stands as the only indication to the hidden artisan football boot factoryimage © designboom

the nike symbol stands as the only indication to the hidden artisan football boot factoryimage © designboom