KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

PRODUCT LIBRARY

watch our livestream talk with BMW Design at 19:15 CEST on monday 15 april, featuring alice rawsthorn and holger hampf in conversation.

connections: +300

the solo show features five collections, each inspired by a natural and often overlooked occurence, like pond dipping and cloud formations.

discover our guide to milan design week 2024, the week in the calendar where the design world converges on the italian city.

connections: 31

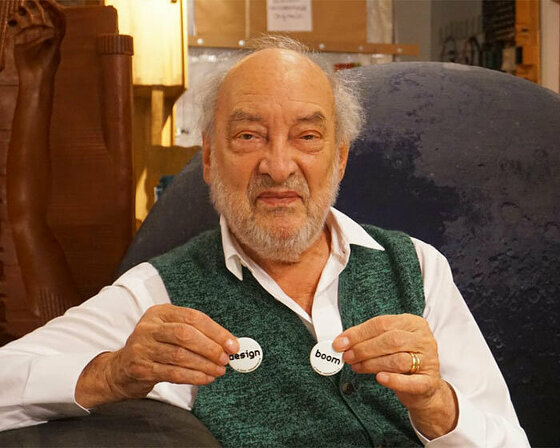

'despite dealing with health-related setbacks, gaetano remained positive, playful and ever curious,' pesce's team said in a post confirming his death.

connections: +130