DIY Casting. Hand plucked Styrofoam molds fit your aluminum handle to you! by howe lindsay from switzerland

designer's own words:

this handle was the result of an aluminum casting experiment, developed with the support of the rapid architectural protyping lab (raplab) during a seminar week at the eth zurich. a block of styrofoam served as the positive form for the model. it was shaped by hand through tearing off spheres of material, piece by piece, until a handle was formed to fit exactly to the producer's hand and design aesthetic. by tearing rather than cutting or lasering the material, the styrofoam form (and accordingly, the final aluminum product) reflected the process of its creation. the prototype was buried in sand and aluminum was cast, immediately consuming the styrofoam with its heat. thus, the positive form also served as a negative form, and it was possible to cast the exact shape without any complex steps or further manipulation. if it were to be produced on a more regular and mass scale, the initial cast could be used again as a negative form. the rawness of the form is directed towards an industrial, technological generation and is appropriate for any door where the user desires a custom-made handle with a little edge.

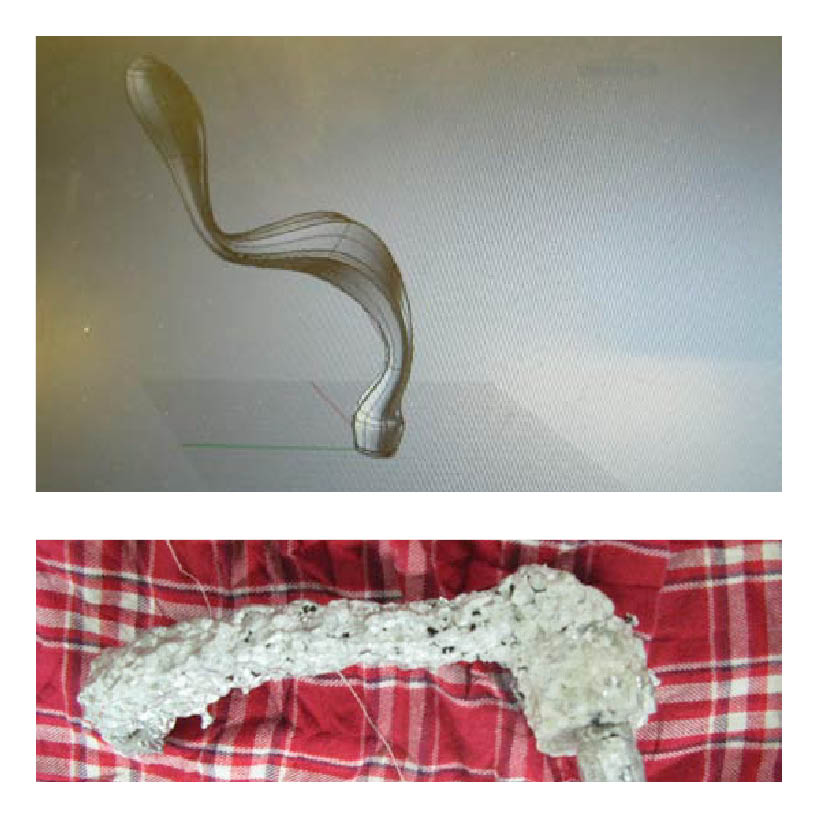

smoothness of initial computer-aided design contrasts with tactile roughness possible in final product

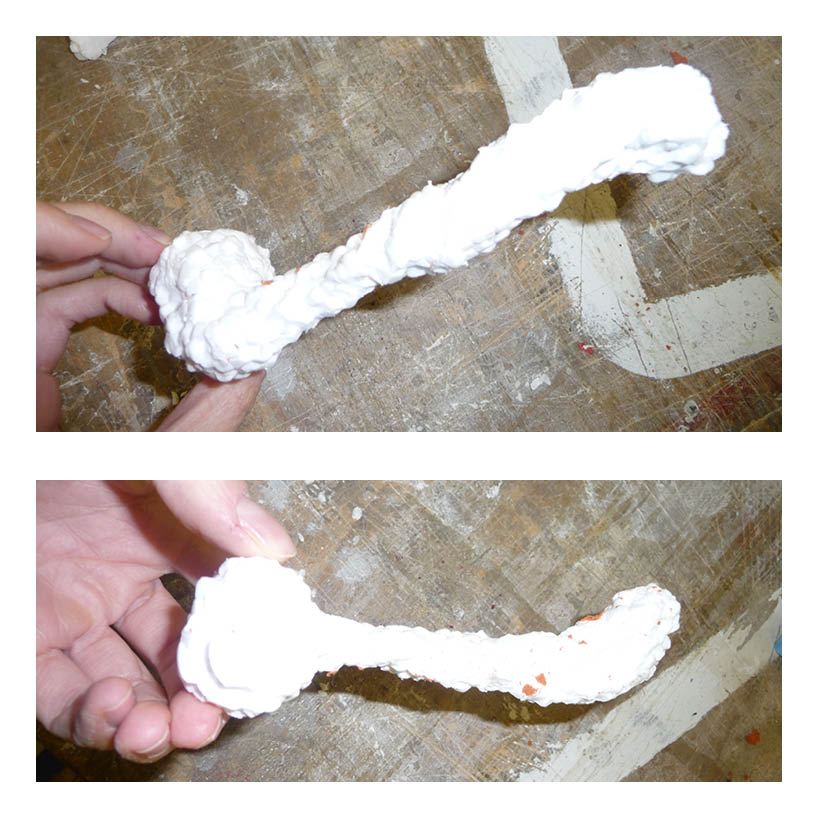

styrofoam prototype carved only with the hand

styrofoam prototype carved only with the hand

positive form covered with sand mixture for aluminum pouring

positive form covered with sand mixture for aluminum pouring

aluminum heats in self-made oven with support from the raplab team

aluminum heats in self-made oven with support from the raplab team

metal is cooled and removed from its formwork

metal is cooled and removed from its formwork

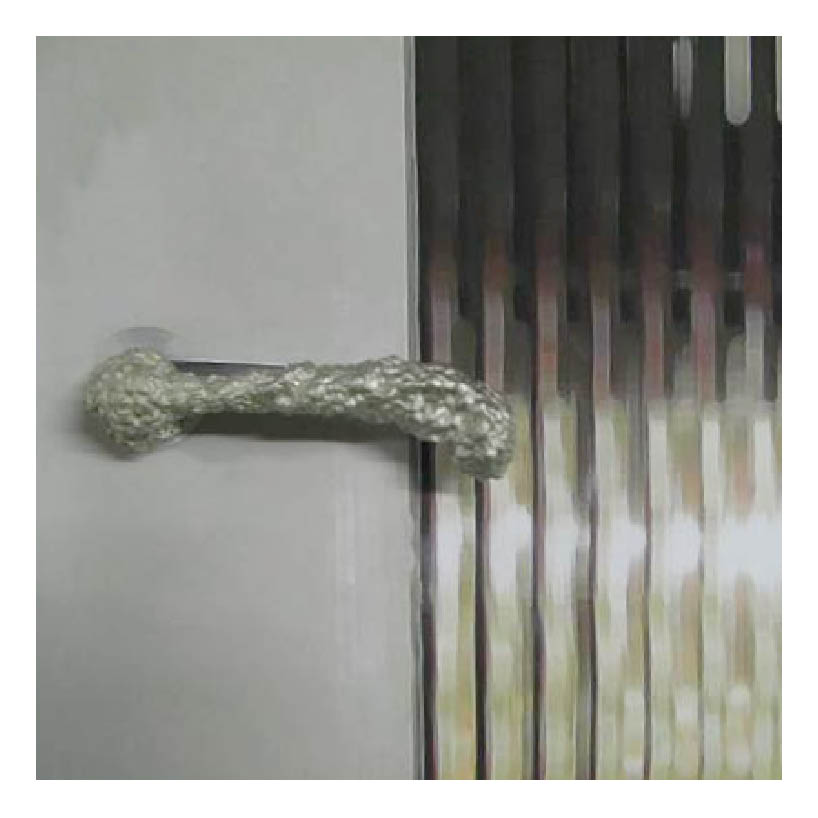

the prototype handle is mounted on a wood and glass door!

the prototype handle is mounted on a wood and glass door!