Renault 4 eco by aashutosh kulkarni from india

designer's own words:

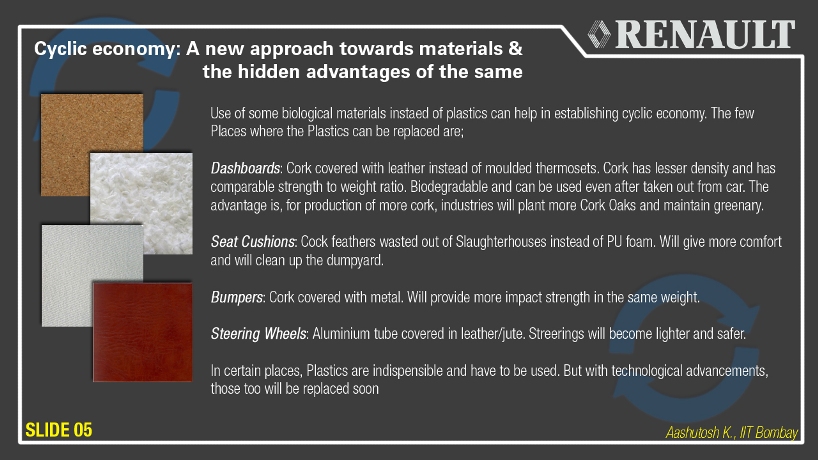

when it comes to incorporating the circular economy on the vehicle industry, we need to think about the sustainable materials. or else, we can think of other way of eradicating the industrial nutrients. all the materials used in the this vehicle will be taken from nature, directly and we will be able to give the nature back what it owns in the form it was previously, instead of chemically modifying it to such a product that keeps on accumulating. plastics are one of the good engineering materials, but unfortunately, no plastic is 100% recyclable and nature doesn't take it back.

today plastic cover majority parts of the car. in some of the applications they have no alternative; but there are a few places, from where, we can remove plastic and go for a material, gifted by nature.

1. dashboard: Currently, these are injection molded components, made up of thermosets. instead of them, we can use "cork bark". when dry, it has lesser density than that of majority of plastics. for instance, rigid pu has density of 1270 kg/m3 while cork has maximum of 240 kg/m3. since the industry will require huge amounts of cork, they will plant more cork trees in vacant lands and will indirectly support the ecosystem. since finishing of the cork is not so good, it can be covered with leather. also, to compensate for the strength, we can make a four fold thick component; but since dashboards hardly carry any mechanical loads, cork can be used. poor fire resistance is another problem with cork, which can be neglected, since the vehicle is not running on internal combustion engine which produces immense heat. cork can be treated with some oils to increase its life also. the cork dust produced during manufacturing has been studied as a potential filler in hydroxypropyl cellulose, a cellulose derived, biodegradable and renewable material, used in food industry.

2. bumpers: thermosets rule the bumper sector of the automobiles. instead of them again, cork covered with metal can be used. cork has a cellular structure and has high shock absorbing capacity. the cells, if aligned along the length of the vehicle, can give good results. again, production and other issues have been discussed earlier. The damaged cork can be thrown away, since it is biodegradable, or can be brought in use for other applications like production of activated carbon and eco-ceramics. A drawback of using cork+metal is limited plasticity. But again, it doesn't matter much when the exterior styling has to depict the minimalistic approach.

3. seats: seat cushions are now a days made up of polyurethane foams. these are non recyclable and non-biodegradable. The frame will be metallic and we require a suitable alternative for foam. so for cushioning, we will go back in past where the cushions used to be filled with feathers. The problem of arrangement of huge quantity of feathers can be solved by looking at the slaughterhouses. kfc, the global chain alone slaughters millions of chickens everyday. the feathers of these birds are considered to be a waste. these can be cleaned and used for the stuffing purpose. these kind of seats, stuffed with feathers and stitched in treated leather, will provide the ultimate comfort. also, it will reduce the slaughterhouse waste by a huge amount. the covering again, can be made up of leather or some soft touch cloth, depending upon the user's choice.

4. steering wheel: usually made up of vinyl resins, can now be made in aluminum tubes. these tubes, when covered is leather, will become lighter and safer. aluminum, in tube form can absorb more shock in case of impact than a fully solid thermoset wheel.

there are certain application where plastics are indispensable. but still, with current rate of advancement, these too will get eradicated. for example, previously, there was no material which was lightweight and transparent. but now scientists have discovered transparent aluminum. also, the organic led displays are capturing the market. so wherever these plastics are to be used, care must be taken that we use bio-degradable or at least a recyclable thermoplastic.

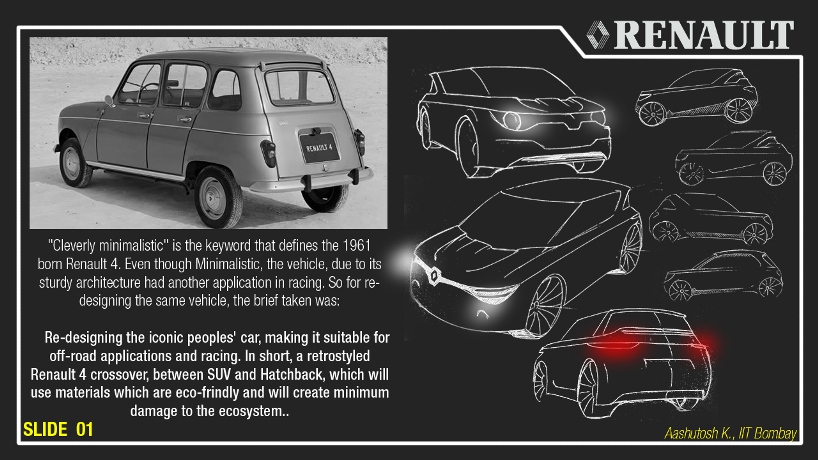

Brief history

Design Direction

Design Direction

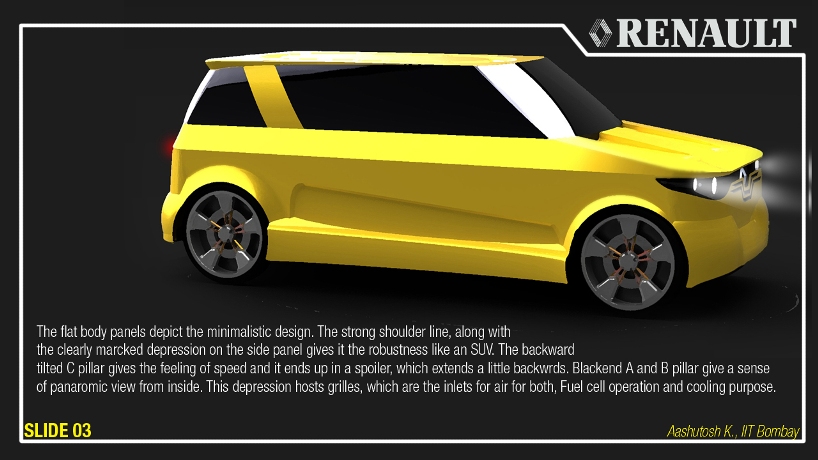

Description of new Renault 4

Description of new Renault 4

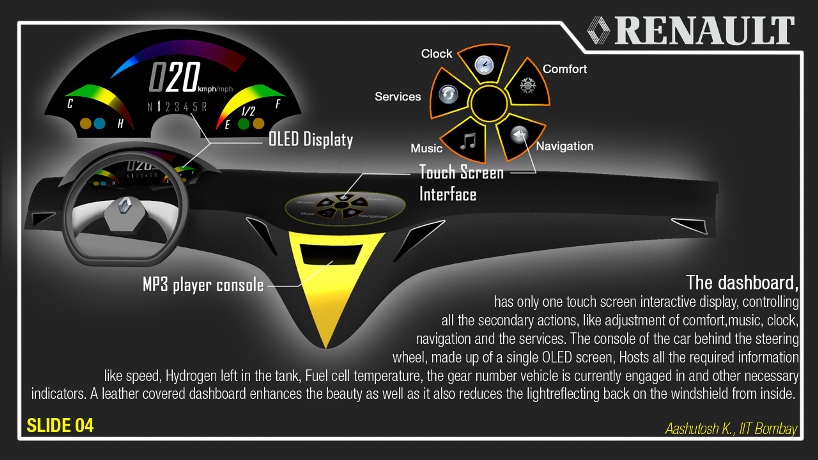

Interiors

Interiors

Cyclic economy

Cyclic economy

Final concept

Final concept