soapmaker by yip shing, jaon ho from china

designer's own words:

Eco-Soapmaker

• DIY soap making

• Fried oil cycling use

• Liquid soap making

Nowadays, The trend of DIY soap is all over the world: US, Europe, Japan, and Taiwan etc.

DIY soap & Liquid soap making

This is a DIY SoapMaker that let user made Organic Soap or Liquid soap

with their own styles and favorite scenes at home more safe, simply and easily. The Soaps can be a gift to friend, self-use and decoration etc.

Recycle fried oil

The Soapmaker can make the fried oil becomes a soap.

Because the Fried Oil after used for fried repeated, oil quality will drop down and it is harmful for health. But if we drop it into the dikes that will cause water pollution problem and waste it.

We can recycle the fried oil as Soap for cleaning purposes, which will contribute to our world and saving cost. Most of housewife they know this concept, but they have faced the problem are the process is quite complex and many tools and container involved. Such as, thermometer, scale, stirrer, numerous containers and tools etc

Soapmaker is a great potential product that not yet on the existing market. Besides, on the market is no an Organizer or products to help the Soap making process simply and more efficient.

Soapmaker can help them to recycle our resource to be useful. Also, that can make fresh & stylish soaps with personal identity, which fulfils the product trend of function value added.

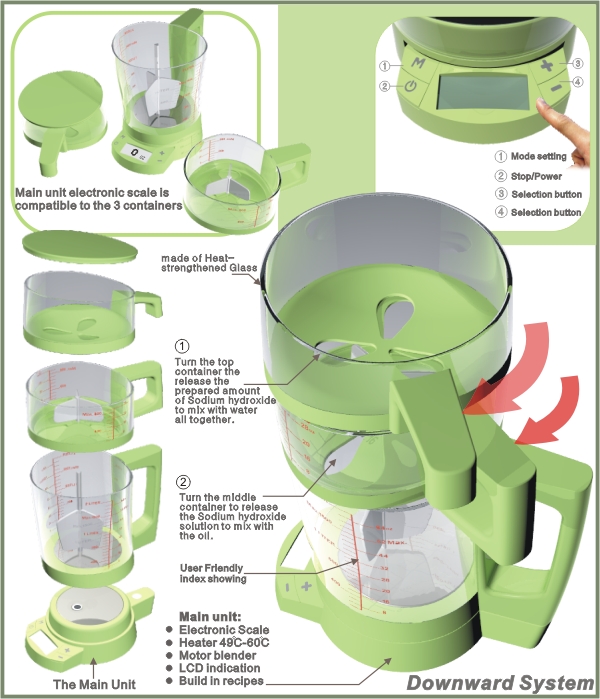

The main unit are included the function of Electronic Scale, Thermostatic Sensor, Heater 49C-60C, Motor blender, LCD indication and Build in recipes. Main unit electronic scale is compatible to the 3 containers.

The Transparent Container is made of Heat-strengthened Glass, because which is good performance on chemical resistance, and high transparence too.

The plastics part will mainly made by PP by Injection molding. PP has good performance on heat resistance and durable

It is completely can be produced into a real product, and ready for the world market.

The Soap Making process with Soapmaker, are the following:

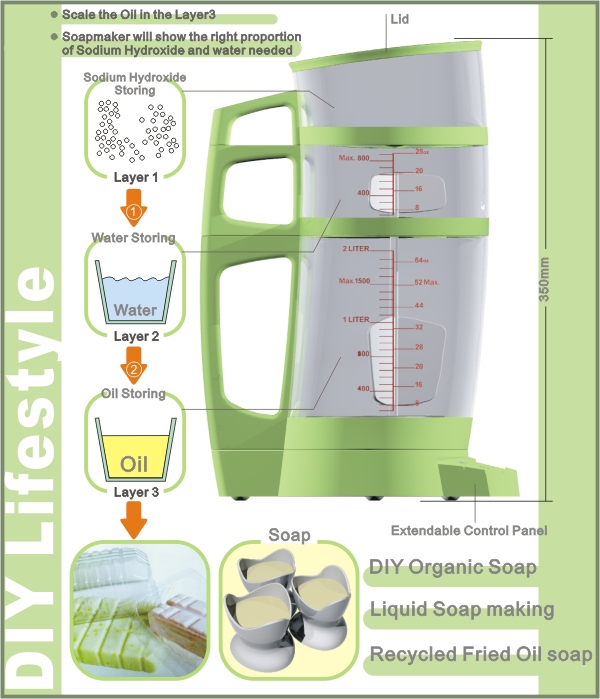

1. Firstly, Scale the Oil in the Layer3, Soapmaker will show the right proportion of Sodium Hydroxide and water needed.

2. Enter the type of oil that you poured into. Then soapmaker will set up the temperature, time, and indicate user to complete the soap automatically.

3. Turn the top container layer to release the prepared amount of Sodium hydroxide to mix with water all together.

4. Stirring in process

5. Turn the middle container to release the Sodium hydroxide solution to mix with the oil.

6. Stirring in process

7. Stir until the chemical reaction occurred that called “trace”. Then, just up to user favorites adding the colorants and essential oils as required.

8. Pour the Soap into the Moulds.

9. Soap Making Process is completed.

Reference website:

http://www.colebrothers.com/soap/

http://www.snowdriftfarm.com/soapsafely.html

http://www.snowdriftfarm.com/form_liquidsoaprecipes.html

http://essencesupply.com/liquid/liquidsoap.html3.

Reference book:

The Handmade Soap Book by Melinda Coss

soapmaker scenario

soapmaker operation 1

soapmaker operation 1

soapmaker operation 2

soapmaker operation 2