KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

PRODUCT LIBRARY

the two films highlight AI's ability to provide insights into global ecosystems, emphasizing its role in analysing data to predict and mitigate risks.

connections: +540

designboom is presenting the sound machines of love hultén at sónar festival in barcelona this june!

connections: 85

BMW releases the upgraded vision neue klasse X, with a series of new technologies and materials especially tailored for the upcoming electric smart car.

following the unveiling at frieze LA 2024, designboom took a closer look at how the color-changing BMW i5 flow NOSTOKANA was created.

connections: +640

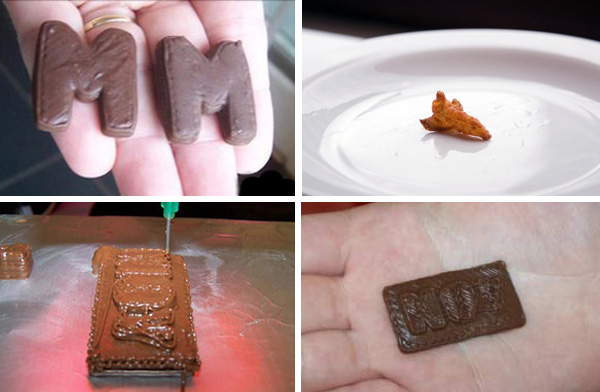

detail view of a piece of chocolate created with the machine

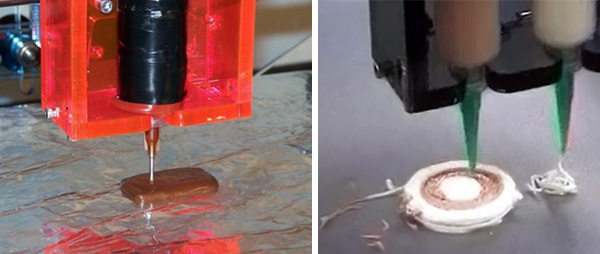

detail view of a piece of chocolate created with the machine examples of the device in use, printing chocolate and frosting shapes

examples of the device in use, printing chocolate and frosting shapes 3D printing offers greater detail and more uniformity across multiple copies of objects than does shaping food by hand

3D printing offers greater detail and more uniformity across multiple copies of objects than does shaping food by hand early collaborations with the french culinary institute in generating food inks

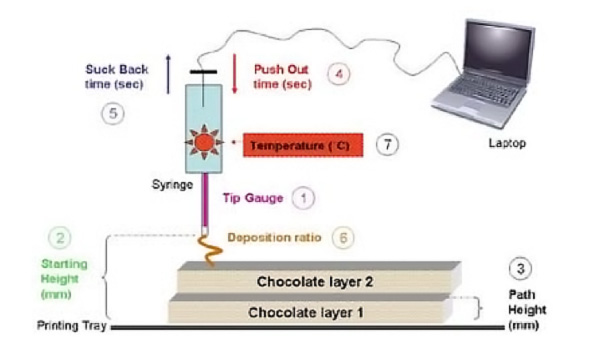

early collaborations with the french culinary institute in generating food inks this diagram illustrates some of the variables that must be adjusted in printing chocolate, suggesting some of the ways in which recipes can be customized pending further developments of the printer

this diagram illustrates some of the variables that must be adjusted in printing chocolate, suggesting some of the ways in which recipes can be customized pending further developments of the printer