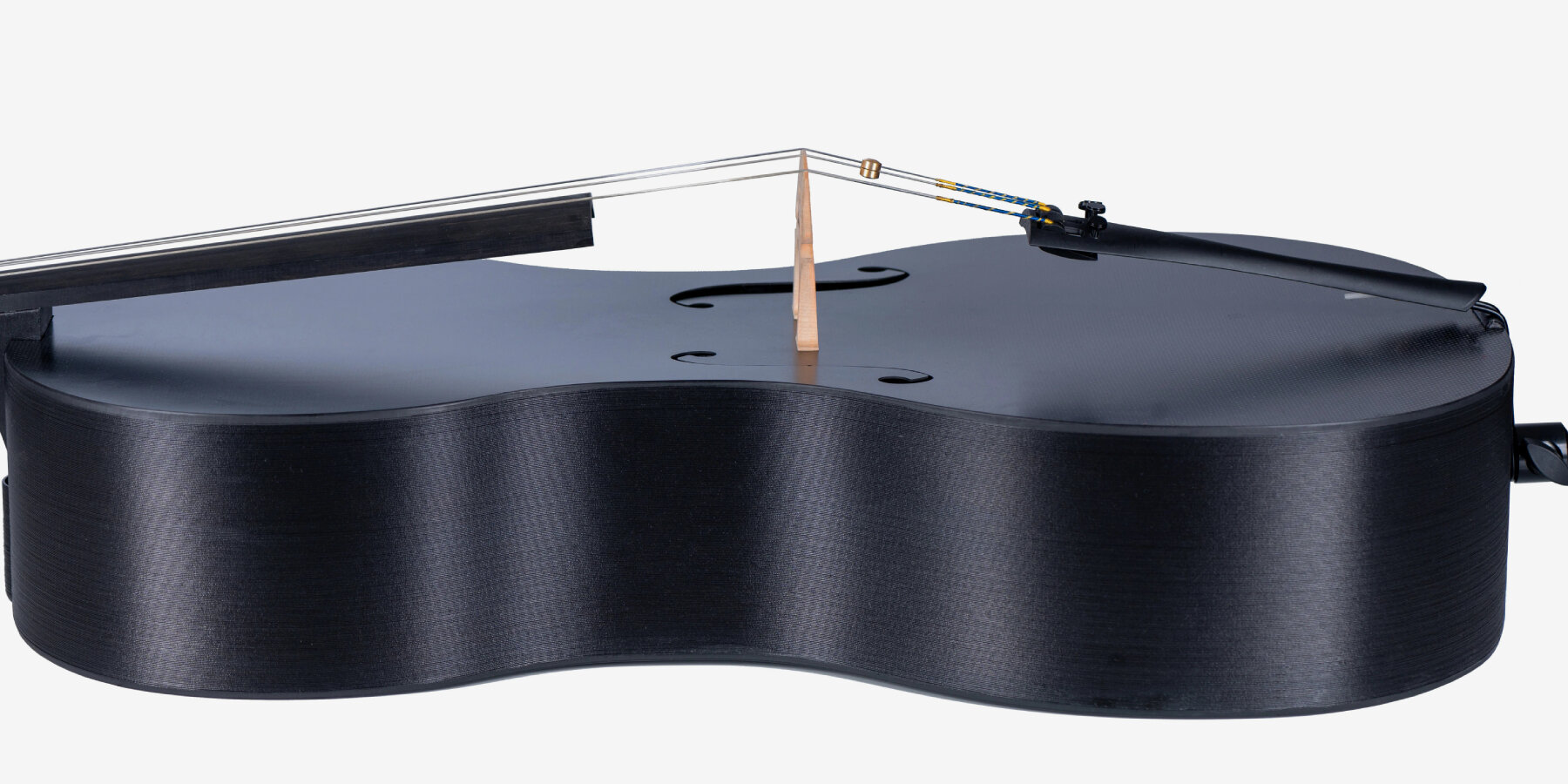

side profile of the cello

rear view of the violin

KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

sized at 35mm, the film cartridge can fit into a pocket, small bag, or even hang as an accessory.

connections: +540

a modular device built around a physical keyboard, the case introduces a full QWERTY typing tool that attaches magnetically.

connections: +480

ori eliminates ribs, fabric, and typical failure points, creating an entirely new category of personal weather device.

connections: 36

the concept trike was inspired by a vision of getting around airports more efficiently.

connections: +430