KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

PRODUCT LIBRARY

BMW releases the upgraded vision neue klasse X, with a series of new technologies and materials especially tailored for the upcoming electric smart car.

following the unveiling at frieze LA 2024, designboom took a closer look at how the color-changing BMW i5 flow NOSTOKANA was created.

connections: +630

each unit draws inspiration from emergence, featuring a hexahedron-based structure that facilitates integration into larger systems.

connections: 96

brian eno revives his color-changing neon turntable for the second time, on display too at paul stolper gallery in london until march 9th, 2024.

connections: +380

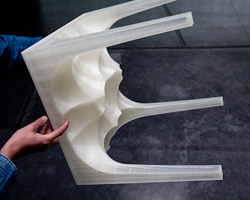

the large scale 3D printed mold | all images courtesy of NOWlab

the large scale 3D printed mold | all images courtesy of NOWlab hot liquid aluminum is poured into the 3D printed cast

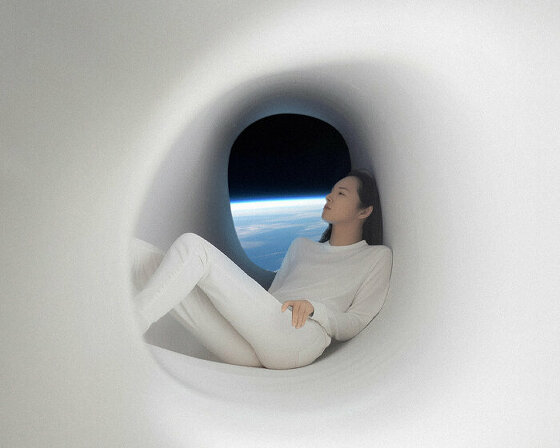

hot liquid aluminum is poured into the 3D printed cast after the exposing process, parts of the stool are getting visible within the mold

after the exposing process, parts of the stool are getting visible within the mold a mathematical algorithm creates the distinctive shape

a mathematical algorithm creates the distinctive shape

the 3D printed aluminum stool detail

the 3D printed aluminum stool detail